4 - 14 Maintenance and Repair

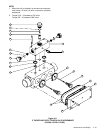

4.10 2" Purge Exhaust

Switching Valve Maintenance

(Model LS1250 only)

WARNING!

Ensure that the Dryer is de-energized, valve isolated,

and fully depressurized before attempting to remove

or disassemble any Dryer component or subassem-

bly. Failure to do so may result in serious personal

injury and/or equipment damage.

Note: Removal of valve body [16] from the dryer manifold

is not required unless replacement of square O-rings [17]

or valve body is necessary.

Note: Exploded view illustrates one-half of switching

valve only. Disassembly of opposite half (not shown ex-

ploded), is identical.

1. Clean and inspect all valve hardware upon disassem-

bly. Replace all software and any hardware which

appears damaged or abnormally worn.

2. Clean and inspect valve seat located inside the valve

body [16]. As previously noted, this can be accom-

plished without removing the valve body [16] from the

dryer manifold.

3. Apply an ultra-thin film of O-ring lubricant to items [3],

[5], [8], [11], and [17] before reassembly. Do not ap-

ply lubricant to the valve seat seal [13].

4. The U-cup piston seal [5] has been fitted with a cut O-

ring. Ensure that the U-cup piston seal is installed on

the valve piston [4] as shown. The open side of the

U-cup piston seal [5] must face the valve cover [2]

upon reassembly.

5. Apply a light coat of lubricant to the sockethead cap

screws, items (1) and (18). Hand tighten screws until

snug. Torque to 245 in-lbs.

2" Switching Valve Components

Item Description Total

1 Sockethead Cap Screw 8

2 Valve Cover 2

3 O-Ring 4

4 Valve Piston 2

5 Piston Seal 2

6 Bonnet Cylinder 2

7 Valve Bonnet 2

8 O-Ring 2

9 Rod Scraper 2

10 Poppet Shaft 2

11 O-Ring 2

12 Seal Retainer 2

13 Valve Seat Seal 2

14 Retaining Disc 2

15 Seal Nut 2

16 Valve Body 1

17 Square O-Ring 2

18 Sockethead Cap Screw 4