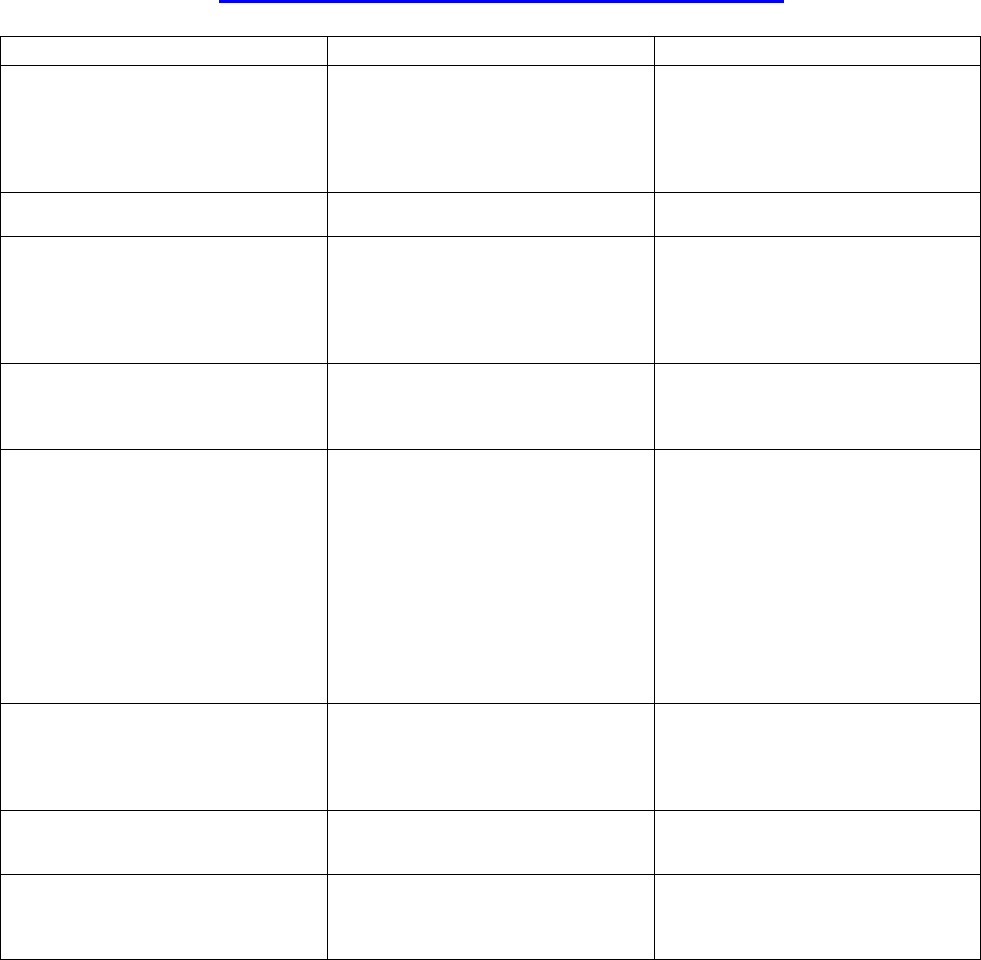

18

Motor Trouble Shooting Guide (General)

Problem Possible Causes Corrective Actions

High current draw (all 3 phases) 1. Low line voltage (5 to 10% lower

than nameplate).

2. 200V motor on 230/240V system.

3. 230V motor on 208V system.

4. Incorrect propeller.

5. Incorrect pitch if adjustable

1. Consult power company.

2. Change to 230V motor.

3. Change to 200V or 280V motor.

4. Consult factory.

5. Reduce pitch / consult factory

Low motor current draw 1. Incorrect propeller.

2. Incorrect pitch if adjustable.

1. Consult factory

2. Increase pitch / consult factory

Unbalanced current

(5% from average)

1. Unbalanced line voltage due to:

A. Power supply.

B. Unbalance system loading.

C. High resistance connection.

D. Undersized supply lines.

2. Defective Motor.

1. Consult power company and/or

electrician.

2. Replace motor.

Excessive voltage drop

(2 or 3% of supply voltage)

1. Inadequate power supply.

2. Undersized supply lines.

3. High resistance connections.

1. Consult power company.

2. Increase line sizes.

3. Check motor leads and other

connections.

Overload relays tripping 1. Overload.

2. Unbalanced input current.

3. Single phasing.

4. Excessive voltage drop.

5. Frequent starting or intermittent

overloading.

6. High ambient starter temperature.

7. Wrong size relays.

8. Improper overload settings of

adjustable relays.

1. Reduce load on motor or increase

motor size.

2. Balance supply voltage.

3. Eliminate.

4. Eliminate (see above).

5. Reduce frequency of starting and

overloading or increase motor size.

6. Reduce ambient temperature.

7. Correct size per nameplate current

and service factor.

8. Readjust to motor FL Amps x S.F.

Motor runs very hot 1. Overloaded.

2. Blocked ventilation.

3. High ambient temperature.

4. Unbalanced input current.

5. Single phased.

1. Reduce overload.

2. Fouled fill or air restriction.

3. Reduce ambient temperature.

4. Balanced supply voltage.

5. Eliminate.

Motor will not start 1. Single phased.

2. Rotor or bearings locked.

1. Shut power off – eliminate.

2. Shut power off – check shaft

rotation.

Excessive vibration (Mechanical)

Out of balance

1. Motor mounting.

2. Motor.

1. Check to be sure motor mounting

hardware is tight.

2. Replace motor.

Note: Consult Warranty page prior to replacing or repairing any cooling tower components. Delta recommendation and consent

to remedy material and workmanship defects is necessary, to avoid breach of Warranty.