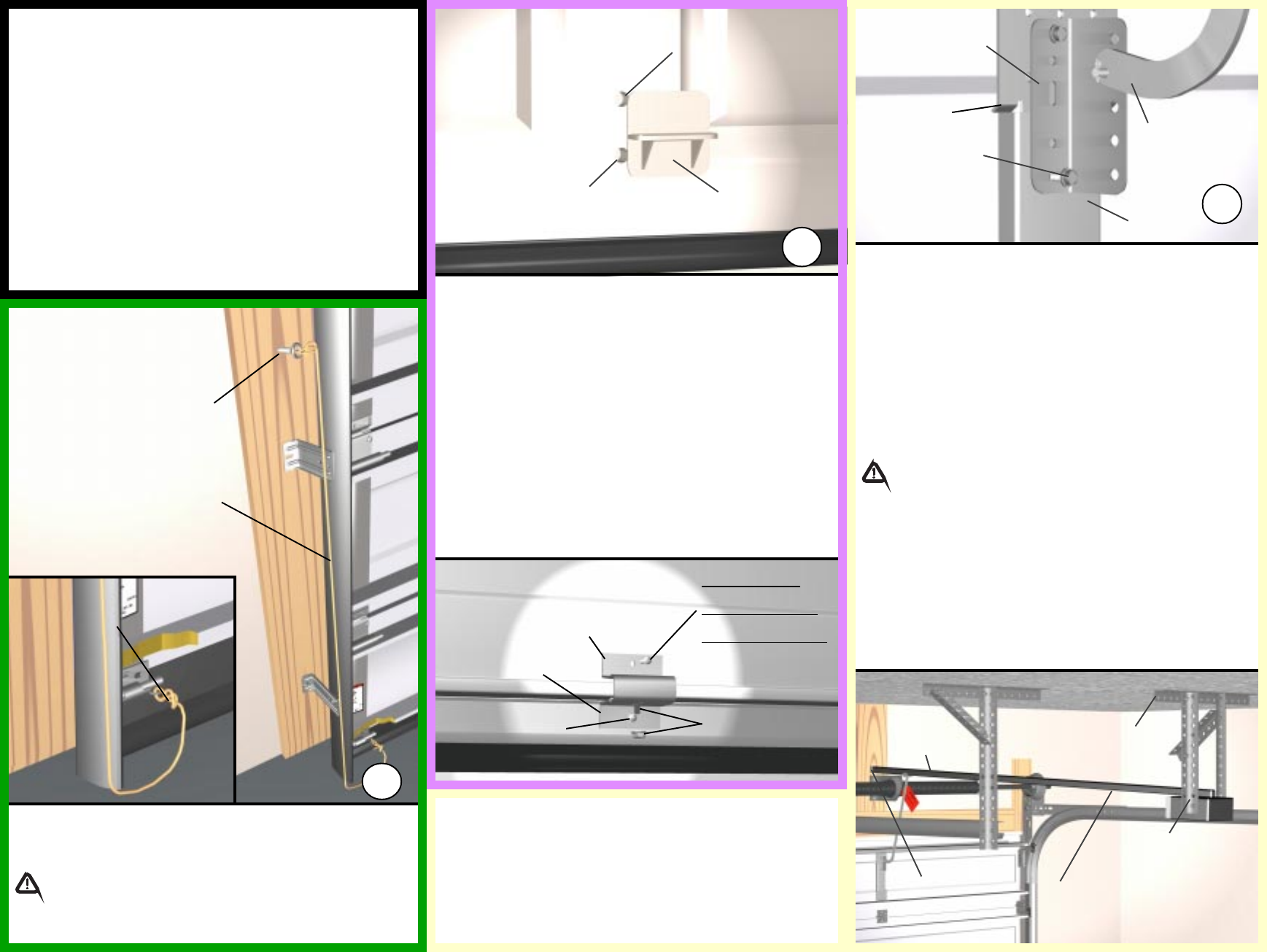

SCREW EYE AT 48 TO 50

(1220 to 1270 mm) FROM FLOOR

PULL ROPE

TIE PULL ROPE TO

BOTTOM BRACKET

19

Twist the No. 6 screw eye into the wood jamb approximately 48 to 50 (1220 to

1270 mm) from the floor. Tie the pull rope to the screw eye and to the bottom

bracket as shown.

WARNING!

DO NOT INSTALL PULL ROPES ON DOORS WITH ELECTRIC OP-

ERATORS. CHILDREN MAY BECOME ENTANGLED IN THE ROPE

CAUSING INJURY OR DEATH.

ATTACH OPERATOR

RAIL SECURELY TO

SPRING PAD

ATTACH OPERATOR

TO CEILING USING

PERFORATED ANGLE

IMPORTANT! ANGLE MUST

BE ATTACHED TO FRAM-

ING MEMBER(S)

INSTALL TROLLEY RAIL 1 TO 1-1/2

(25 - 38 mm) ABOVE DOOR WHEN

FULLY OPEN (RAIL WILL SLOPE

DOWN)

INSTALL FRONT OF

TROLLEY RAIL 1

TO 1-1/2 (25 - 38

mm) ABOVE HIGH-

ARC OF DOOR

TYPICAL OPERATOR

BRACKET (SUPPLIED

WITH OPERATOR)

SCREWS (SUPPLIED

WITH OPERATOR)

TYPICAL OPERATOR

ARM (SUPPLIED

WITH OPERATOR)

SEE OPERATOR INSTRUCTIONS

FOR DETAILS ON INSTALLATION

OPERATOR

MUNTIN

21

INSTALLATION TIPS:

1. Follow the installation instructions supplied with your operator.

2. Reinforce top section per manufacturers recommendation prior to attaching

operator.

3. Install trolley rail 1 to 1-1/2 (25 - 38 mm) above high arc of top section of

the door.

4. Mount operator to ceiling so that 1 to 1-1/2 (25 - 38 mm) clearance is

maintained between trolley rail and top section when door is fully open (trolley

rail will slope down towards rear).

5. The operator bracket must be mounted to the operator muntin on the top

section so it bridges the transition point in section thickness.

WARNING!

OPERATOR MUST BE TESTED AT TIME OF INSTALLATION AND

MONTHLY THEREAFTER TO ENSURE THAT DOOR REVERSES ON

CONTACT WITH 2 X 4 BOARD LAID FLAT UNDER THE DOOR. FAIL-

URE TO ADJUST OPERATOR, IF NECESSARY, CAN RESULT IN SE-

VERE INJURY OR DEATH. IF YOUR OPERATOR IS EQUIPPED WITH

PHOTOELECTRIC SYSTEM, THEN THIS MUST BE TESTED AT THE

SAME TIME TO ENSURE THAT DOOR DOES NOT CLOSE AND A

CLOSING DOOR OPENS IF SYSTEM IS OBSTRUCTED. FAILURE

TO MAKE ADJUSTMENTS, IF NECESSARY, CAN RESULT IN SEVERE

INJURY OR DEATH.

BRIDGE POINT

If the door still does not operate easily, lower the door into the closed position,

UNWIND THE SPRING(S) FULLY (Reference the insert sheet Removing the

Old Door/Preparing the Opening section on Torsion Spring Removal), and re-

check the following the items:

1.) Check the door for level.

2.) Check the torsion tube for level.

3.) Check the track spacing.

4.) Check the counterbalance cables for equal tension.

5.) Check for track for potential obstruction of the rollers.

6.) Clamp locking pliers onto track and rewind spring(s).

IMPORTANT! If door still does not operate properly, then contact a qualified

door agency.

OUTSIDE

STEP PLATE

BOTTOM SECTION

(OUTSIDE)

1st HOLE AT 1

(25 mm) FROM

BOTTOM OF

SECTION

2nd HOLE AT 2-3/16

(56 mm) FROM 1st HOLE

BOTTOM SECTION

(INSIDE)

20

INSIDE STEP

PLATE BASE

To install the step plate raise the door to a comfortable working height and

secure with locking pliers to the track. Locate the step plate in the center of

any stile on a raised panel door. Make one mark 1 (25 mm) up from the

bottom edge and another mark 2- 3/16 (56 mm) up from the first mark. Drill

a 7/16 (11 mm) hole through the section at each mark and insert the step

plate. Loosely fasten step plate slide to base with (1) 1/4-20 x 1/2 carriage

bolt and nut. Align inside step plate holes and fasten from inside using the #8

screws provided. Install one #8 x 3/4 screw in the bottom step plate hole. In

the top hole use the #8 x 3/4 screw when attaching step plates to 9200

Foamcore, use the #8 x 1 screw when attaching step plates to 9600

Thermogard

®

and use the #8 x 1-1/2 screw when attaching step plates to 9900

Thermowayne. Tighten 1/4-20 carriage bolt and nut.

NOTE: Step plates are optional on 9900 Thermowayne, 9600 Thermogard

®

,

and 9200 Foamcore door models.

TYPICAL OPERATOR INSTALLATION

If you are installing an electric operator on your door, the following informa-

tion is provided to ensure proper function of your door/operator installation.

Figure 21 shows a typical means of connecting the operator arm to the opera-

tor stile located in the center of the top section.

INSIDE STEP

PLATE SLIDE

1/4-20 X 9/16

CARRIAGE BOLT

AND WHIZ NUT

#8 x 3/4 SCREW

#8 x 3/4 SCREW

9200 FOAMCORE

#8 x 1 SCREW

9600 THERMOGARD

#8 x 1-1/2 SCREW

9900 THERMOWAYNE