THGIEHROOD1-LT2-LT3-LT

"0'6

KCART"46

)mm6261(

MOTTOBMOTTOBA/N

"5'6

KCART"96

)mm3571(

ELDDIMMOTTOBA/N

"6'6

KCART"07

)mm8771(

ELDDIMMOTTOBA/N

"8'6

KCART"27

)mm9281(

MOTTOBMOTTOBA/N

"0'7

KCART"67

)mm0391(

ELDDIMMOTTOBA/N

"3'7

KCART"97

)mm7002(

MOTTOBMOTTOBMOTTOB

"6'7

KCART"28

)mm3802(

ELDDIMELDDIMELDDIM

"9'7

KCART"58

)mm9512(

ELDDIMELDDIMELDDIM

"0'8

)SNOITCES4(

)SNOITCES5(

KCART"88

)mm5322(

ELDDIM

POT

ELDDIM

POT

ELDDIM

ELDDIM

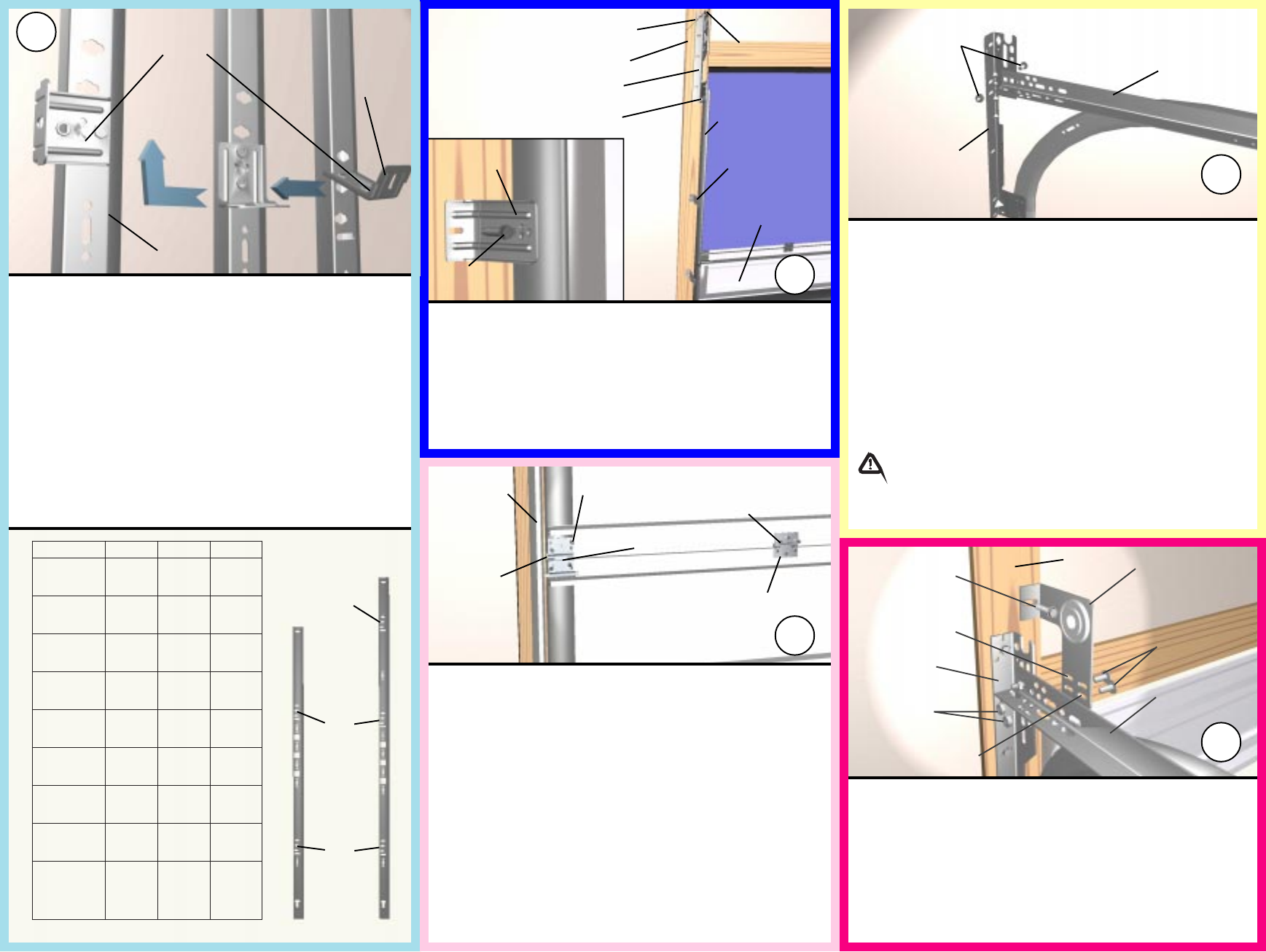

FLAGANGLE

HORIZONTAL

ANGLE

ALIGN

EDGE OF

SECTIONS

(2) 1/4-20 x 5/8 SELF

TAPPING SCREWS

END HINGE #1

ON BOTTOM

SECTION

BOTTOM JAMB

BRACKET

VERTICAL

TRACK

NOTE:

IDENTIFY LOCK

SECTION BY THE

#2 STAMP ON

THE END HINGE

5/16 x 1-5/8

LAG SCREW

CENTER

HINGE

(3) 1/4-20 x 5/8 SELF

TAPPING SCREWS

TL-3

HOLES

TL-1

HOLES

TL-2

HOLES

BOTTOM

SECTION

VERTICAL

TRACK

FLAGANGLE

5/16 x 1-5/8

LAG SCREW

CENTER JAMB

BRACKET

COUNTERBALANCE

CABLE

CABLE DRUM

ROUND

NOTCH

NOTE: Jamb brackets are stamped for identification.

Position the first vertical track over the rollers of the bottom section. Make

sure the counterbalance cable is located between the rollers and the door jamb.

Align the marks on the vertical track from step 3 with the vertical track line

stamp on the endcap and loosely fasten bottom jamb bracket and flagangle with

(1) 5/16 x 1-5/8 lag screw each, but do not secure the center jamb bracket yet.

Install the other vertical track the same way. Run the counterbalance cables up

between vertical track and edge of door section. Hang the cables over the tops

of the the flagangles in round notch.

IMPORTANT! The tops of the vertical tracks must be level from side to side.

Make sure top leaves of all hinges on the bottom section are folded down.

Insert rollers into the end hinges of the second section, also called the lock

section. With assistance lift section and place rollers over the tops of the

vertical tracks. Install by guiding rollers into the vertical track on both sides

and gently lowering this section onto the bottom section. Keeping the ends of

the sections aligned, install remaining section(s), except top section, in same

manner. Fasten all hinges to connect the sections by flipping up the hinge leaf,

holding it firmly against section and driving in the supplied 1/4-20 x 5/8 self

tapping screws.

NOTE: Two (2) 1/4-20 x 5/8 self tapping screws are used for each end hinge

leaf, while three (3) screws are used for each center hinge. The screw place-

ment is staggered in the end hinges, with the screw nearest the edge of the door

going into the lower hole and the inside screw going into the upper hole.

IMPORTANT! Once fastener is snug against hinge leaf, tighten an additional

1/4 to 1/2 turn to achieve maximum design holding power.

NOTE: To install lock, see lock instructions included in the lock assembly bag.

To install horizontal track, place the curved end over the top roller. Align the

key slot in the track with the quick install tabs on the flagangle. With a

pivoting motion, push the curved portion of the horizontal track downward to

lock into place, while raising the rear of the horizontal to align the horizontal

angle with the flagangle. Bolt the horizontal angle to the flagangle using (1)

3/8-16 x 3/4 truss head bolt and nut. Repeat for other side. With track

installed you can adjust the top brackets. Vertically align the top section with

the lower sections. Once aligned, move adjustable slide out to force top roller

against horizontal track. Tighten 1/4-20 nuts to secure slide to top bracket.

Repeat for other side. Remove nail that was temporarily holding top section in

place.

IMPORTANT! Failure to remove nail before attempting to raise door could

cause permanent damage to top section. DO NOT ATTEIMPT TO RAISE

DOOR AT THIS POINT.

WARNING!

DO NOT RAISE DOOR UNTIL HORIZONTAL TRACKS ARE SECURED

AT REAR AS OUTLINED IN STEP #18, OR DOOR COULD FALL FROM

OVERHEAD POSITION CAUSING SEVERE INJURY OR DEATH.

6

7

11

3/8-16 x 3/4

TRUSS HEAD

BOLT & NUT

Attach the left hand end bearing bracket to the horizontal angle with

(2) 3/8-16 x 3/4 truss head bolts and nuts. Once the bracket is secured, fasten

the bracket to the jamb with (1) 5/16 x 1-5/8 lag screw. Repeat for the right

hand side.

NOTE: End bearing brackets are to be attached using the lower slots on 12

radius track and using the upper slots on 15 radius track.

IMPORTANT! Right and left hand are always determined from inside the build-

ing looking out.

LEFT HAND END

BEARING BRACKET

UPPER SLOTS

USED ON 15

RADIUS TRACK

(2) 3/8 - 16

HEX NUTS

FLAGANGLE

LOWER SLOTS USED

ON 12 RAD. TRACK

5/16 X 1-5/8

LAG SCREW

(2) 3/8-16 x 3/4

TRUSS HEAD

BOLT

HORIZONTAL

ANGLE

12

JAMB

JAMB

BRACKET

ALIGN IN PROPER

HOLE AND TWIST TO

BACK OF TRACK

VERTICAL TRACK

3

Measure the length of the vertical tracks. Using the table, determine the

placement of the jamb brackets for your door height. Align the Twistlock

wings on each jamb bracket with the correct butterfly hole in the track and turn

the jamb bracket perpendicular to the track so the mounting flange is toward

the back leg of the track.