FLAGANGLE

(2) 5/16 x 1-5/8

LAG SCREW

TOP SECTION

NOTE: CABLE SHOULD

BE BETWEEN TRACK

AND DOOR AND

BEHIND ROLLERS

10

8

TOP BRACKET

(4) 1/4-20 x 5/8

SELF TAPPING

SCREWS

1

ST

SET OF HOLES ON

9900 THERMOWAYNE

2

ND

SET OF HOLES ON

9600 THERMOGARD

®

3

RD

SET OF HOLES ON

9200 FOAMCORE

3 U-BAR

TOP SECTION

TOP RIB

FOAMCORE II

(MODEL 9200)

TOP SECTION

1/4-20 x 5/8 SELF

DRILLING SCREW

(2) 1/4-20

CARRIAGE BOLTS

AND NUTS

TOP BRACKET

SLIDE

ROLLER

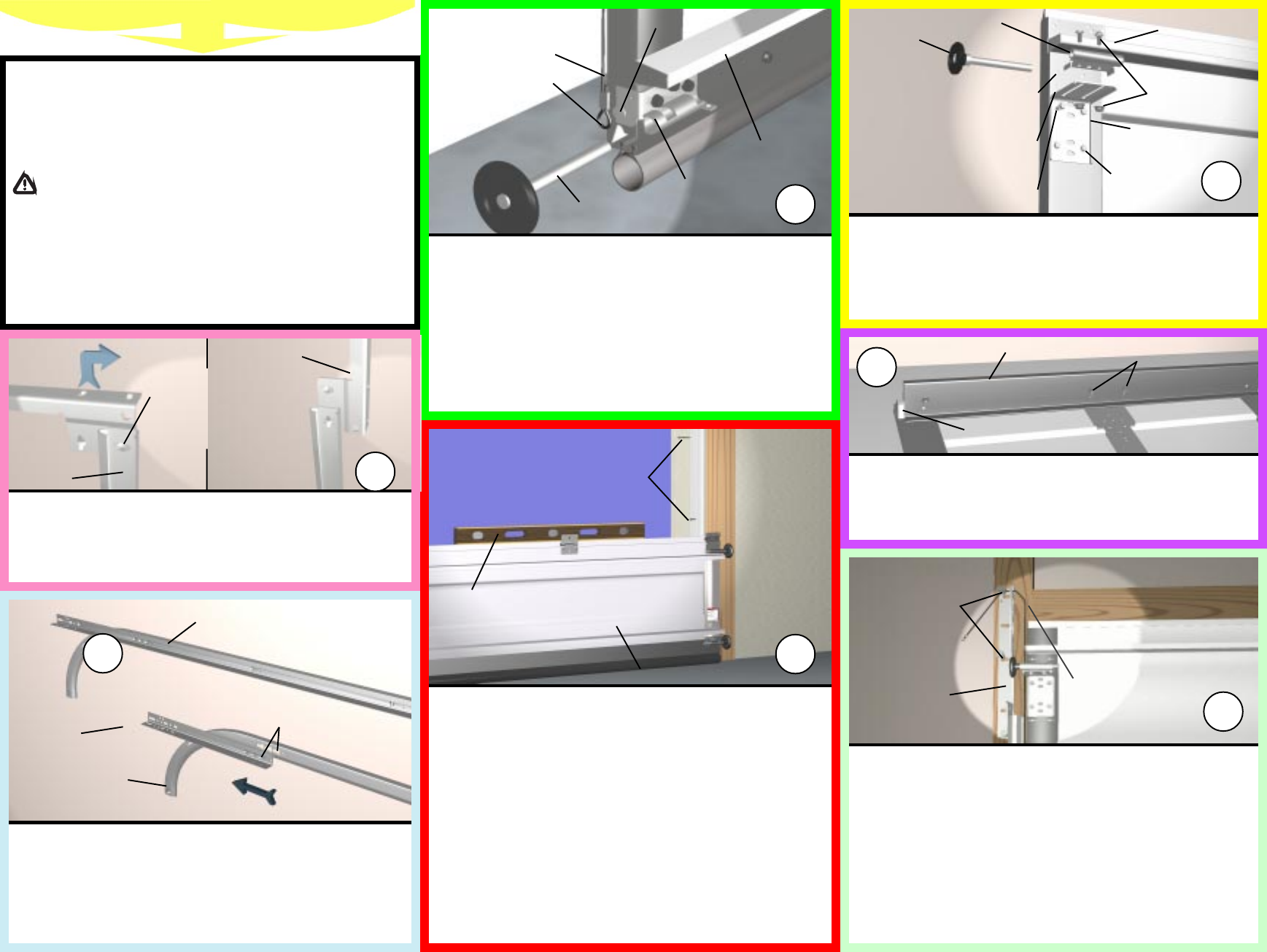

To install the L-shaped top brackets, align the top holes in the top bracket with

the first set of holes in the endcap for 9900 Thermowayne doors, second set

for 9600 Thermogard

®

doors and third set on all 9200 Foamcore doors.

Fasten using (4) 1/4-20 x 5/8 tapping screws. Secure the top bracket slide to the

bracket using (2) 1/4-20 carriage bolts and nuts. Insert rollers.

9200 Foamcore doors over 13 wide require a 3 U-Bar. Center the U-Bar over

the top rib on the top section and secure it to the section using (6)

1/4-20 x 5/8 self drilling screws. Place top section in the door opening and

secure it temporarily by driving a nail into the header near the center of the door

and bending it over the section. Now flip, hold and fasten the hinges.

9

TOP SECTION

RIB

LEFT HAND

BOTTOM

BRACKET

BOTTOM

SECTION

ROLLER

COUNTERBALANCE

CABLE FOR LEFT HAND

DRUM

CABLE LOOP

BOTTOM ASTRAGAL

LEVEL

VINYL WEATHER STRIPPING

TEMPORARILY NAILED TO JAMBS

(REFER TO INSERT SHEET ON

PREPARING THE OPENING.)

MILFORD

PIN

4

FLAGANGLE

ALIGN TAB INTO

TOP HOLE IN

TRACK AND

TWIST UP UNTIL

PARALLEL WITH

TRACK

ALIGN TABS INTO SLOTS,

PUSH TOGETHER AND TAP

FORWARD WITH HAMMER

START HERE

5

1

IMPORTANT! READ IMPORTANT SAFETY NOTICES AND REFER TO

INSERT SHEET INSTRUCTIONS TITLED REMOVING THE OLD DOOR/

PREPARING THE OPENING. IF THE INSERT SHEET INSTRUCTIONS

ARE NOT INCLUDED, CONTACT WAYNE-DALTON CORP. FOR A FREE

COPY.

If removing an existing door, carefully follow the directions given on the

insert sheet instruction in the portion titled Removing the Old Door.

WARNING!

REMOVAL OF AN EXISTING DOOR CAN BE DANGEROUS. FOLLOW

INSERT SHEET INSTRUCTIONS CAREFULLY, OTHERWISE SERIOUS

INJURY OR DEATH COULD RESULT.

Begin the installation of the door by checking the opening. It must be the same

size as the door. Vertical jambs must be plumb and the header level. Side

clearance, from edge of door to wall, must be minimum of 3-1/2 (89 mm) on

each side. For proper opening preparation refer to the portion of the insert

sheet instructions titled Preparing the Opening.

Assemble the Wayne-Dalton Twistlock, Slidelock track system. First,

put the Twistlock tabs on the flagangle into the Twistlock holes on the vertical

track. Give the flagangle 1/4 turn to lock in place.

NOTE: Twistlock track components - U.S. patent no. 5,408,724 and

5,568,672.

Align the Slidelock tabs on the applicable horizontal angle with key slots in

the horizontal track. Push the parts together. Using a hammer, tap the hori-

zontal angle towards the curved end of the track until the hole in track and angle

are aligned. Set tracks aside.

NOTE: For larger size doors, a full length horizontal angle is already spot

welded to the horizontal track.

Uncoil the counterbalance cables and slip the loops at the ends of the cables

over the milford pins on the bottom brackets of the bottom section. Place a

roller in each of the bottom brackets, as well as the end hinges at the top of the

section.

IMPORTANT! Right and left hand is always determined from inside the

building looking out.

Before installing the bottom section, measure and cut vinyl jamb weather-

stripping for entire garage door opening. Temporarily nail the weather-strip-

ping to the door jambs and header. This will help hold the bottom door section

in place. Refer to the insert sheet on preparing the opening.

Now comes the single most important step in installing the Wayne-

Dalton garage door system. Center the bottom section in the door open-

ing. Level it using wooden shims under the bottom astragal as needed. Once

the bottom section is level, all the other components will automatically align.

Hold the section in the opening while attaching vertical tracks. Align the

bottom of the vertical tracks with the bottom of the section. If you leveled the

bottom section with shims on one side, then the vertical track on that side

must be raised off the floor an amount thats equal to the thickness of the

shim(s).

80 HORIZONTAL ANGLE

Position the flagangle 1-11/16 (43 mm) from the edge of the door. Tighten the

first lag screw then secure flagangle to the jamb with (2) 5/16 x 1-5/8 lag

screws.

IMPORTANT! Ensure that flagangles are parallel with the door sections.

IMPORTANT! The dimension between the flagangles must be exactly door-

width plus 3-3/8 (86 mm) for smooth, safe door operation.

Now complete the vertical track installation on both sides by securing center

jamb bracket and tightening other lag screws.

22-1/2

HORIZONTAL

ANGLE

HORIZONTAL

TRACK

VERTICAL

TRACK

2