Teledyne Analytical Instruments

2-8

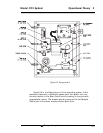

2 Operational Theory Model OT-2 System

2.6 Sample System

The system consists of a shut off valve, particulate filter, pres-

sure regulator, scrubber, calibration selector valve, flow control

valve, O

2

transmitter and a sample flow meter and incorporates ¼

inch tube fittings for sample inlet and outlet connections at the

side of the enclosure.

H

2

S from the sample gas can diffuse into the Micro-Fuel Cell

leading to the formation of lead sulphide with the anode material.

To eliminate the deleterious effect of H

2

S on the sensor, the scrub-

ber is filled with Purafil

®

.

Sample Flow Description

: (See Figure 2-4)

1. The sample enters the transmitter system via the shut off valve

at 6-40 psig and passes through the filter where particulates, to

90 microns, are trapped.

2. A pressure regulator, which has been preset at the factory to

approximately 5 psig ensures a constant gas flow to the sensor.

3. After the pressure regulator, the sample gas passes through the

scrubber to the calibration selector valve.

4. When the sample has been selected, it flows through the flow

control valve to the O

2

sensor.

5. Finally, the sample flows through the flow meter and exits the

system through the vent line to a safe area at atmospheric

pressure.

Note: The flow control valve should be adjusted until the

flow meter indicates a flow rate of 0.4 scfh.

Figure 2-4 Flow Diagram

SAMPLE IN

6-40 PSIG

FILTER

H2S

SCRUBBER

SPAN GAS IN

O2 XMTR

0-10 PPM

FLOWMETER

.1-1.0 SCFH

VENT TO

ATMOSP H ERE

PRESSURE

(SAFE AREA)