14 Single-Speed/Ramp-Hold

Problem: Controller display

turns on. No heat in kiln.

■

Is the relay making its normal clicking sound?

Test the elements with an ohmmeter:

Element Resistance Test

UNPLUG kiln/disconnect the power. Open the

kiln’s switch box. Make sure the wires connecting

the relay to the elements are secure. If connec

-

tions are okay, continue to step 2:

Touch theohmmeter leadsto thetwo elementcon

-

nectors of each element. A no-needle-movement

reading on an analog meter, or OPEN on a digital

meter, indicates a broken element.

If the elements check out okay, replace the relay.

Note: To replace relay, see your kiln’s instruction and

service manual.

We knowthe controlleris receivingvoltage, becausethe

display is lit. But the voltage from the transformer may be

too lowto powerthe relays. Performthe “ControllerPower

Input Test,” page 13. If your controller passes the Input

Test, perform the “Controller Power Output Test”:

Controller Power Output Test

Is thecontrollersending voltageto therelay? TestOUT-

PUT with a voltmeter:

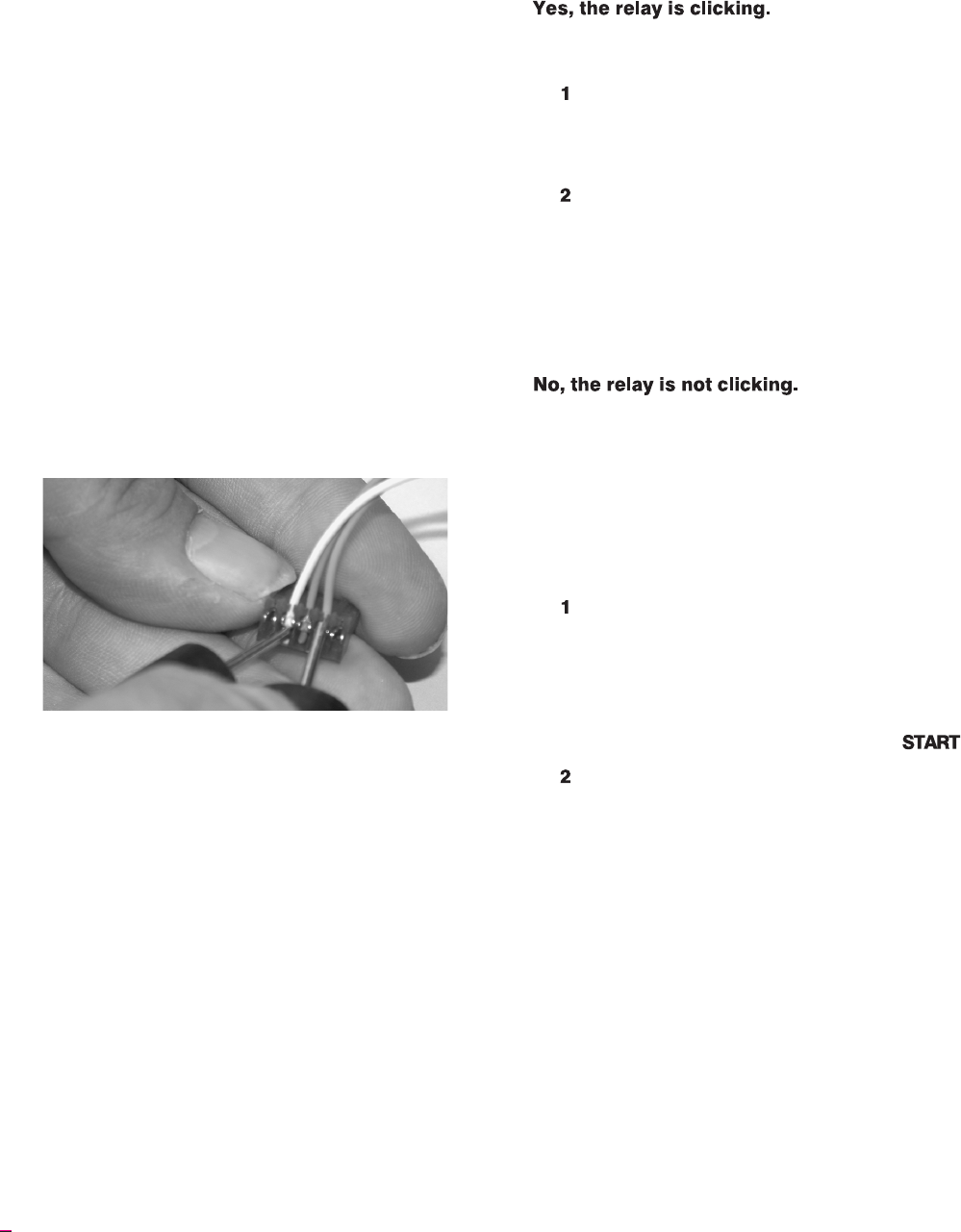

UNPLUG the kiln/disconnect the power. Remove

the 4 screws holding thecontroller faceplate tothe

switch box. Lift faceplate out of box and let the

controller hang on the outside of the box with the

back of the board facing you. Then plug the kiln

back in. Program thecontroller to fire to 1000°F at

FULL rate in Ramp-Hold mode. Press .

Put the voltmeter in DC mode. (It must be in DC

mode when testing OUTPUT voltage.) Touch

probes to the red wire and black wire connections.

Measure voltage when the relay clicks on.

Output Test Result: No voltage at red and black wires

The controller is not sending power to the relay. Return

the controller for repair or replacement.

Output Test Result: 10 - 14 v. at red and black wires

The controller issending correct power to therelay. Un

-

plug kiln/disconnect power. Remove the kiln switch box.

Look for disconnected wires between the controller, relay

and elements. Check the wiring diagram to be sure wires

are connectedto thecorrect terminals.Be sureconnections

are tight. If the wiring is okay, replace the relay.

Note: To replace relay, see your kiln’s instruction and

service manual.

(in AC mode) to both INPUT connections (the white and

orange wires). (See photo on previous page.)

CAUTION: Do not let the back of the board touch a

grounded object. Make sure the voltmeter is in the AC

modewhen placingthe probeson INPUTconnections.

Controller Power Input Test Result: No voltage

UNPLUG kiln. Check the switch box for disconnected

wires between the cord, transformer, and controller. If wir

-

ing is okay, replace the transformer.

Controller Power Input Test Result: 20 - 24 volts AC

Correct current is reaching the board from the trans

-

former. But since the board is not lighting up, it is probably

defective.Returnthe controllerfor repairor replacement.

Controller Power Input Test Result: less than 20 volts

Did you recently replace the transformer? It may be the

wrong voltage.The voltageis below 20,which is notenough

power for the controller. To find out the cause of low volt

-

age, continue below:

Controller Input Test #2

The back of the board is still facing you and the kiln is

pluggedin. Removethe INPUTplug,which isthe white,or

-

ange,and bluewires, fromtheback ofthe controller.Touch

a voltmeter probe to the white wire and the other probe to

the orange wire.

Input Test #2 Result: Less than 20 Volts AC

There are two possible reasons: 1) Low voltage at the

wall receptacle; 2) defective transformer. If wall receptacle

voltage is correct, replace the transformer.

Input Test #2 Result: 20 - 24 Volts AC

The transformer is sending correct voltage to the con

-

troller. Yet when the INPUT plug was connected to the

controller,voltage wasless than20. This meansthe control

-

ler is draining the voltage and may bedefective. Return the

controller for repair or replacement.

Input Test #2 with disconnected plug: Touch the voltmeter

probes to the white and orange wires to test voltage going to

the controller. The voltmeter must be in AC mode.