12 Single-Speed/Ramp-Hold

FE Error Messages

FE 1 Memory Read/Write Failure

FE 2 RAM Failure

FE 3 OEM Factory Data Corruption

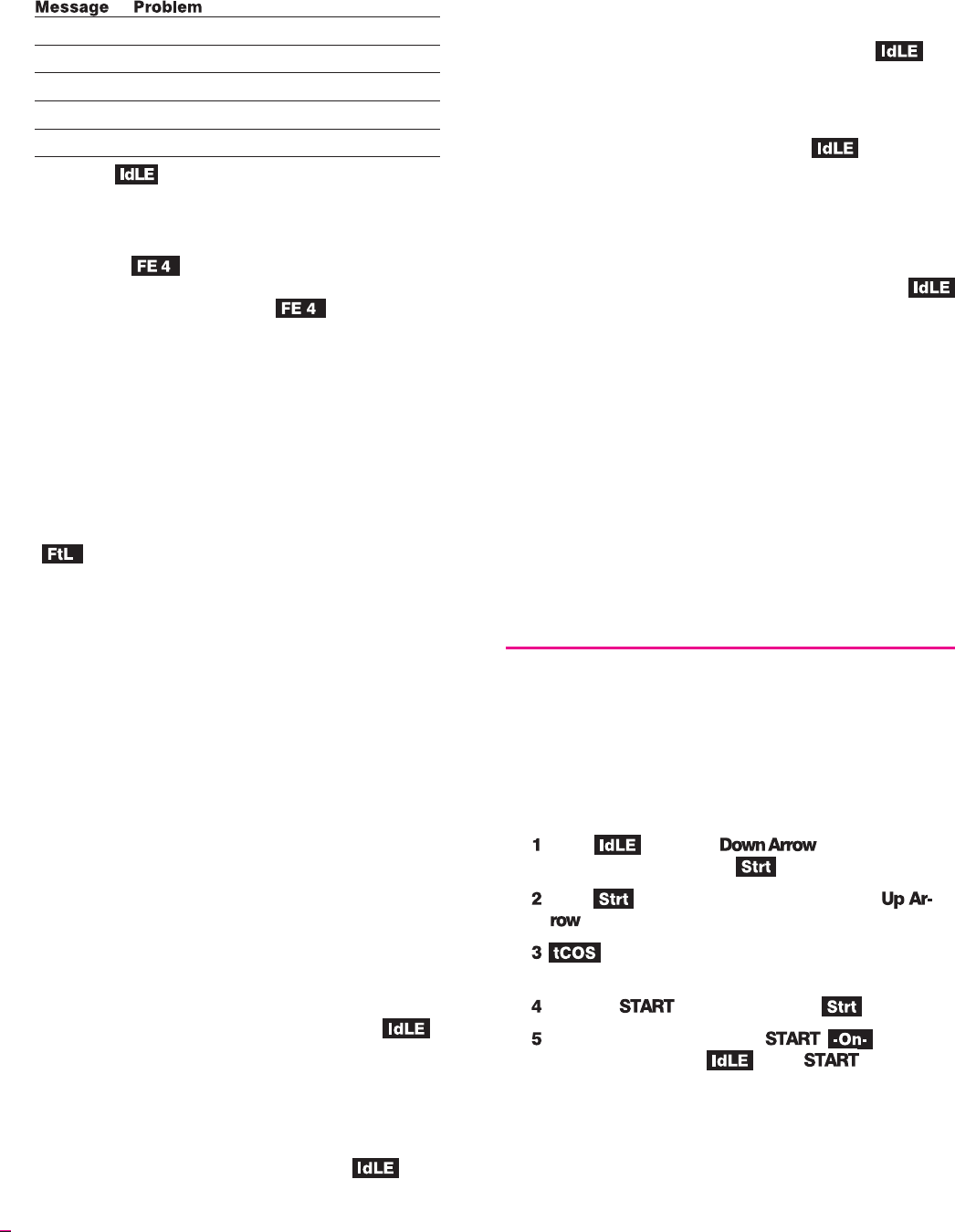

FE 4 Thermocouple “Noise”

FE 5 Software Error

To return to from an FE code

Trypressing anykey.If thatdoesn’t work,turn thepower

off for 10 seconds. Call the factory if the error message re

-

mains when you turn the power back on.

If you getan message, checkthe wire connections

going from the back of the controller to the thermocouple.

A loose connection can cause the message.

FtL / Fired Too Long

This message appears when both of the following condi

-

tions are met:

■

The temperature rise or fall is less than 27°F / 15°C per

hour.

■

The firing is 2 hours longer than programmed.

Programminga coolingsegmenttargettemperaturethat

is below or even close to room temperaturecan also trigger

the message.

See “Controller display turns on. No heat in kiln,” page

14.

HtdE / High Temperature

Deviation

Causes:

■

During a heating-up ramp or a hold, the temperature is

100°F / 56°C above the programmed temperature.

■

During a cooling-down segment, the temperature is

100°F / 56°C higher than the segment’s starting temper

-

ature.

■

A fast rate caused the controller to overshoot the target

temperature.

Also, check for a stuck relay.

PF 1 / Power Failure

The power failed during a cooling segment, and the kiln

cooled pastthe targettemperature while thepower was off.

The kiln will not resume firing. To return to the dis

-

play, press any key.

PF 2 / Power Failure

The power failed during firing andkiln temperature was

below 212°F / 100°C when the power came back on. The

kiln will not resume firing. To return to the display,

press any key.

PF 3 / Power Failure

Thepower failedduring firingand temperaturedropped

more than 72°F / 40°C by the time the power came back on.

The kiln will not resume firing. To return to the dis

-

play, press any key.

tC / Thermocouple Failure

The thermocouple failed during the display. See

the "paperclip" test under "FAIL," page 11.

tCL / Thermocouple Lag

Theheating rateis slowerthan 9°F/ 5°Cperhour andthe

controller temperature is more than 100°F / 56°C away

from the actual kiln temperature. To return to the

display, press any key. Causes:

■

On kilns that use a portable controller, the thermocou

-

ple has fallen out of the firing chamber.

■

A barespoton thethermocouple leadwireshas touched

a grounded object inside the kiln switch box causing the

thermocouple to short out.

Checkfor wornor burnedoutelements, defectiverelays,

low voltage and defective thermocouple.

tCr / Thermocouple Reversed

Thermocouple lead wires are reversed. Check that the

thermocouple lead wires are connected to the correct ter-

minals. See your kiln’s wiring diagram.

Thermocouple

Offset

You can adjust the controller to fire up to 20°F / 11°C

hotter or cooler than the zero factory setting.

From , pressthe key.After rate,

temperature, hold, etc., will appear.

With shown in the display, press the

key.

will appear. Press the arrow keys to change

the controller temperature.

Pressthe keytoreturn tothe display.

To fire the controller, press . will ap

-

pear.Or toreturn to ,press twomore

times.