11

(pages 7, 8) These

are Ramp-Hold programs stored in memory.

etc. (Rate) (page 8) This appears in

Ramp-Hold programming for each segment. 1, 2,

etc. are segment numbers. Enter the rate of temper

-

ature change for that segment. Rate is figured in de

-

grees of temperature change per hour. Example:

A temperature rise of 100° in two hours = 50° rate.

A temperature dropof 200° in onehour = 200°rate.

(page 6)

These are preset firing rates, or speeds, in Sin

-

gle-Speed mode.

(Skip Step) (page 8) This message appears

when you press the key during a

Ramp-Hold firing. You can skip out of a segment

into the next segment.

The firing was stopped by pressing

.

The "Ready to Start" message appears after

programming a firing. Press to begin firing.

Thermocouple Offset (press the ) and De-

lay (press the ) are accessed from the

message.

Thermocouple Offset (Page 12). Adjust the

controller to fire hotter or cooler.

Error Messages

bAdP / Bad Programming

The kiln will not fire because a) the Ramp-Hold pro

-

gram just entered has a rate of 0000 in segment 1, or b) the

target temperature in Single-Speed or segment 1 of

Ramp-Hold is lower than the current temperature.

EtH / Electronics Too Hot

The circuit board temperature is above 176°F / 80°C.

Press any key to return to .

To lower the board temperature, use a fan to blow air

across thekiln switch box into thelouvers. (But donot blow

air into the kiln’s peepholes.) If you have more than one

kiln in the room, place them farther apart. Never allow the

firing room temperature to exceed 110°F / 43°C. (Measure

room temperature three feet away from the kiln.)

FAIL / Thermocouple Failure

The thermocouple, ortemperature sensor, failedduring

firing. Causes:

■

Defective thermocouple or disconnected/loose wires

■

Defective controller

■

Electrical noise

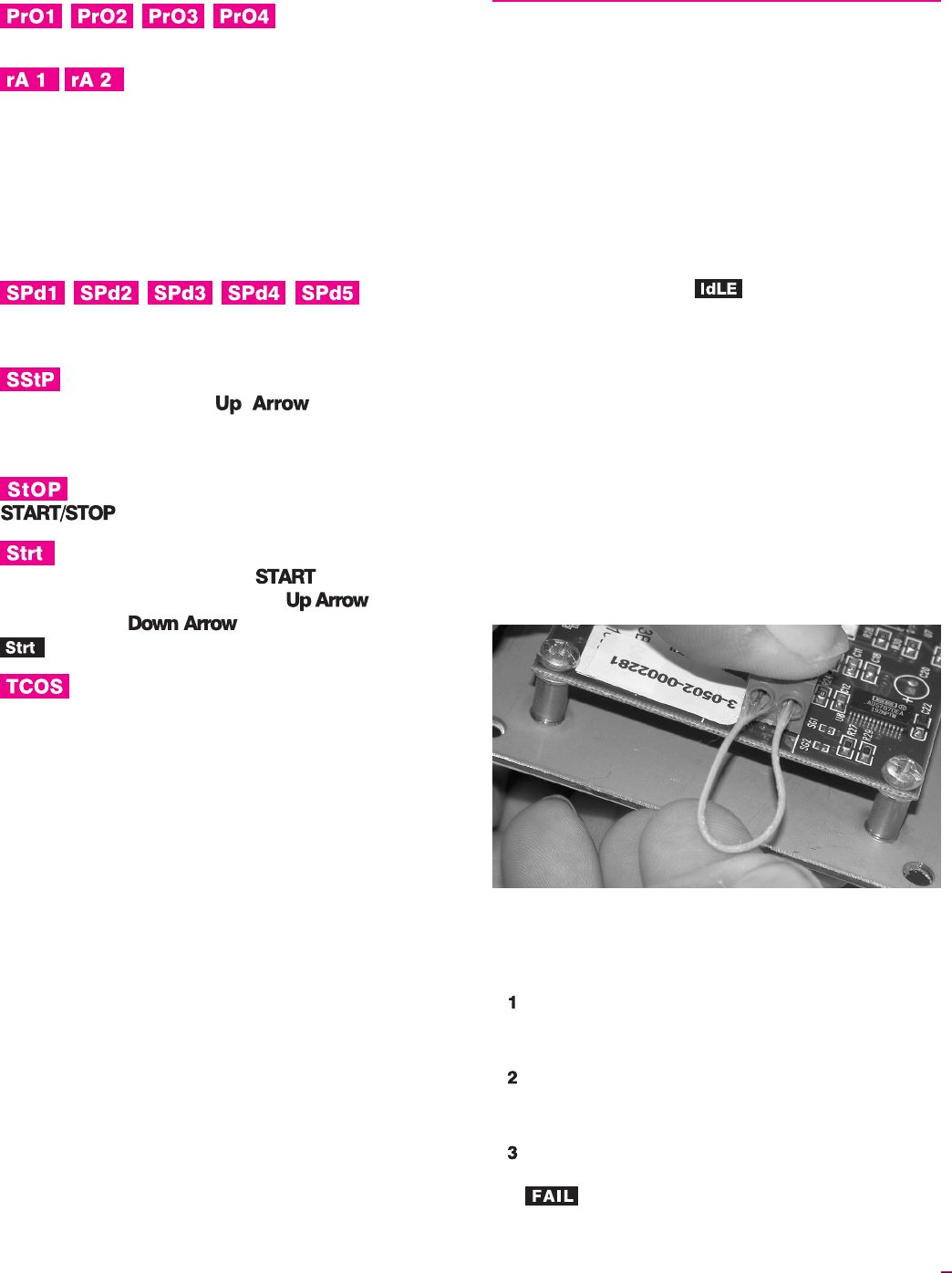

Thermocouple Paperclip Test

Check the thermocouple wire connections. (See your

kiln instruction manual.) If connections are tight, perform

this test:

UNPLUG the kiln or disconnect the power. Re

-

move thecontroller. Removethe twothermocouple

wires from the back of the controller.

Cut a thin paperclip in half. Insert a U-shaped

paperclip piece, or other piece of thin wire, where

you removed the thermocouple wires.

Plug in the kiln. If the controller displays room tem

-

perature, replace the thermocouple. If it shows

, return the controller for repair or

replacement.