14

WARNING

Most batteries are not sold with instructions. How-

ever, warnings are frequently noted on the cell

caps. Read them carefully.

1. Remove the battery boxes from the wheelchair. Re-

fer to

INSTALLING/REMOVING BATTERY BOXES

in PROCEDURE 8 of this manual.

2. Remove the battery caps from the battery.

3. Squeeze the air from the hydrometer.

4. Place the hydrometer into a battery cell.

NOTE: DO NOT fill hydrometer more than 3/4 full.

5. Draw up sufficient acid to cover float balls.

6. Tap lightly to remove air bubbles.

7. Number of floating balls indicates charge.

NUMBER OF FLOATING BALLS

0 Discharged

1 25% Charged

2 50% Charged

3 75% Charged

4 100% Charged

* 5 Overcharged

* Check charging system.

8. Flush the liquid back into the same cell after reading

the float. Repeat this step until all cells have been

properly read. A shorted or dead cell can be detected

when it is the only cell that doesn’t charge.

9. Flush hydrometer in cold running water by allowing

the water to rise into the hydrometer as far as pos-

sible. Do this several times to guard against burn

damage.

10. Replace the battery caps.

11. Install the battery boxes onto the wheelchair. Refer to

INSTALLING/REMOVING BATTERY BOXES in

PROCEDURE 8 of this manual.

FIGURE 2 - USING HYDROMETER TO CHECK

BATTERY CELLS (LEAD ACID)

Number of Floating

Balls Will Vary

According to Charge

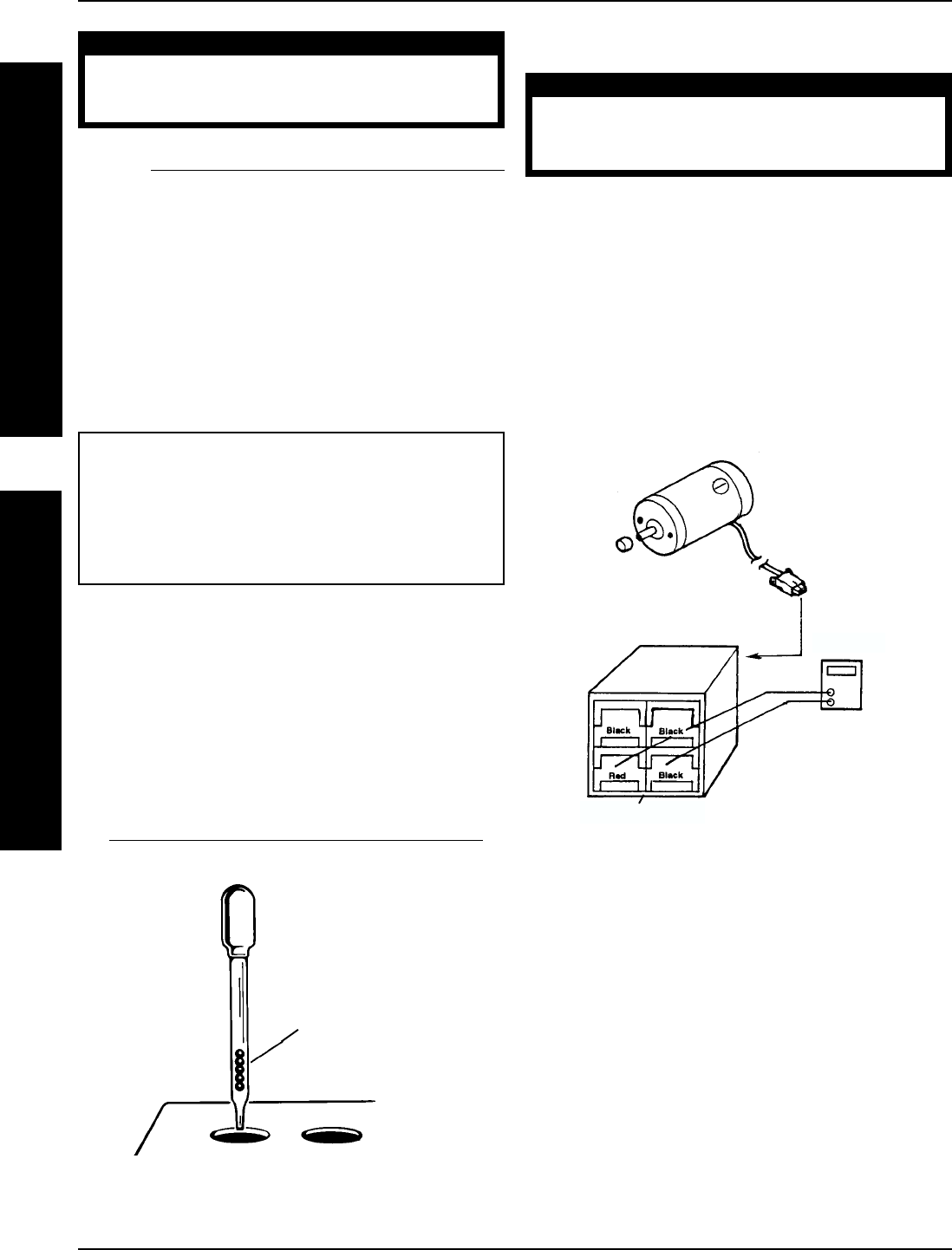

FIGURE 3 - MOTOR TESTING

MOTOR TESTING (FIGURE 3)

WARNING

Invacare recommends that the following proce-

dures be performed by a qualified service tech-

nician.

1. On the 4-pin motor connector, locate the two (2) con-

tacts in the red and black housings.

2. Set the digital multimeter to measure ohms.

3. Measure the resistance between the two (2) motor

contacts.

NOTE: A normal reading is between 1 and 5 ohms

(

Ω

). A reading of 0 ohms (

Ω

) or in excess of 15 ohms

(

Ω

) indicates a problem. High readings are generally

caused by bad connections and/or damaged brushes.

Contact authorized dealer or Invacare.

Ohmmeter

Motor Connector

T

R

O

U

B

L

E

S

H

O

O

T

I

N

G

SAFETY INSPECTION/TROUBLESHOOTINGPROCEDURE 2

S

A

F

E

T

Y

I

N

S

P

E

C

T

I

O

N