15

5.0 Inspection

NOTICE

The information listed in this section is intended to supplement Section 5.7 of the ER2OM.

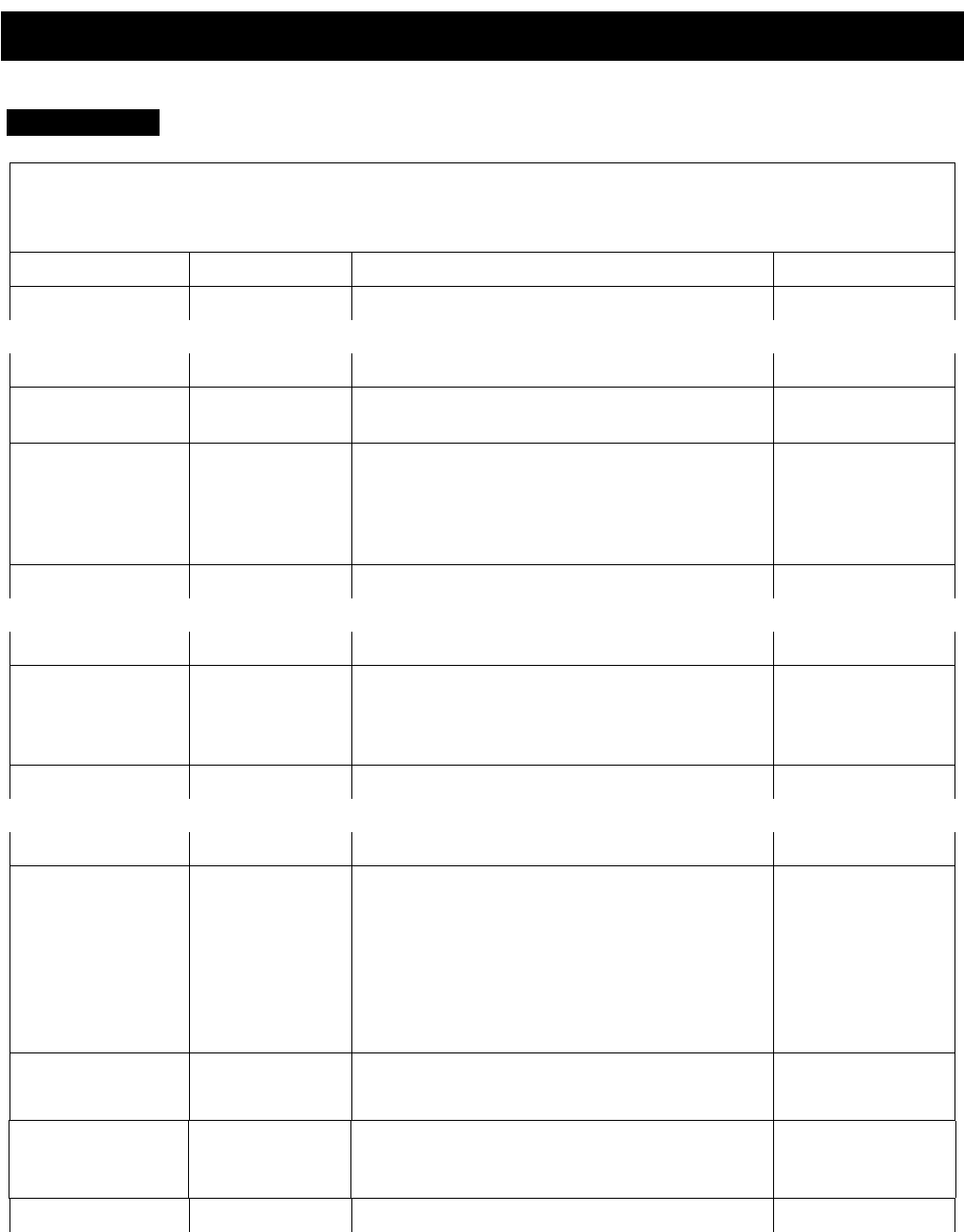

Table 5-3 Hoist Inspection Methods and Criteria

Use this table in conjunction with Table 5-3 of the ER2OM. The entries in this table replace in their entirety

the corresponding entries in Table 5-3 of the ER2OM.

Item Method Criteria Action

Hooks - Fretting

wear

Measure The "u" and "t" dimensions should not be less

than discard value listed in Table 5-4

Replace.

Hooks - Stretch Measure The "k" dimension should not be greater than 1.15

times that measured and recorded at the time of

purchase (See Section 3.6). If recorded "k"

values are not available for hooks when new, use

nominal "k" values from Table 5-4.

Replace.

Load Chain - Pitch

and Wire Diameter

Measure The "P" dimension should not be greater than

maximum value listed in Table 5-5. The "d"

dimension should not be less than minimum value

listed in Table 5-5.

Replace. Inspect

Load and Idle

Sheaves.

Load Chain –

Reeving and

Evening

Visual Chain should be reeved properly through Load

and Idle Sheaves - refer to Section 6.4. Chain,

Chain Springs, Stoppers, and Chain Pin should be

installed properly - refer to Section 3.2. For

double body hoists, chain should be evenly

distributed – equal length of chain in each chain

container or equal lengths of chain on no-load

side of each hoist body.

Reeve/Install chain

properly.

Lower hook until

lower limit switch is

activated on both

hoist bodies.

Chain Springs Visual

Chain springs should not be deformed or

compressed. Refer to Table 5-6 for Chain Spring

dimensions.

Replace.