48

Options and Technical Data

*K=Mean effective load factor.

DUTY CLASSIFICATIONS

Operation Time Ratings at K=0.65*

Uniformly Distributed Infrequent

Work Periods Work Periods

Max. ON

Hoist Max. ON Max. No. Time From Max. No.

Duty Time of Cold Start of

Class Typical Areas of Application (min/hr) Starts/hr (min) Starts

H2

Light machine shop fabricating, service and maintenance; loads 7.5

75 15 100

and utilization randomly distributed; rated loads infrequently handled (12.5%)

H3

General machine shop fabricating, assembly, storage, and 15

150 30 200

warehousing; loads and utilization randomly distributed (25%)

High volume handling in steel warehouses, machine shops, fabricating

30

H4 plants and mills, and foundries; manual or automatic cycling operations

(50%)

300 30 300

in heat treating and plating; loads at or near rated load frequently handled

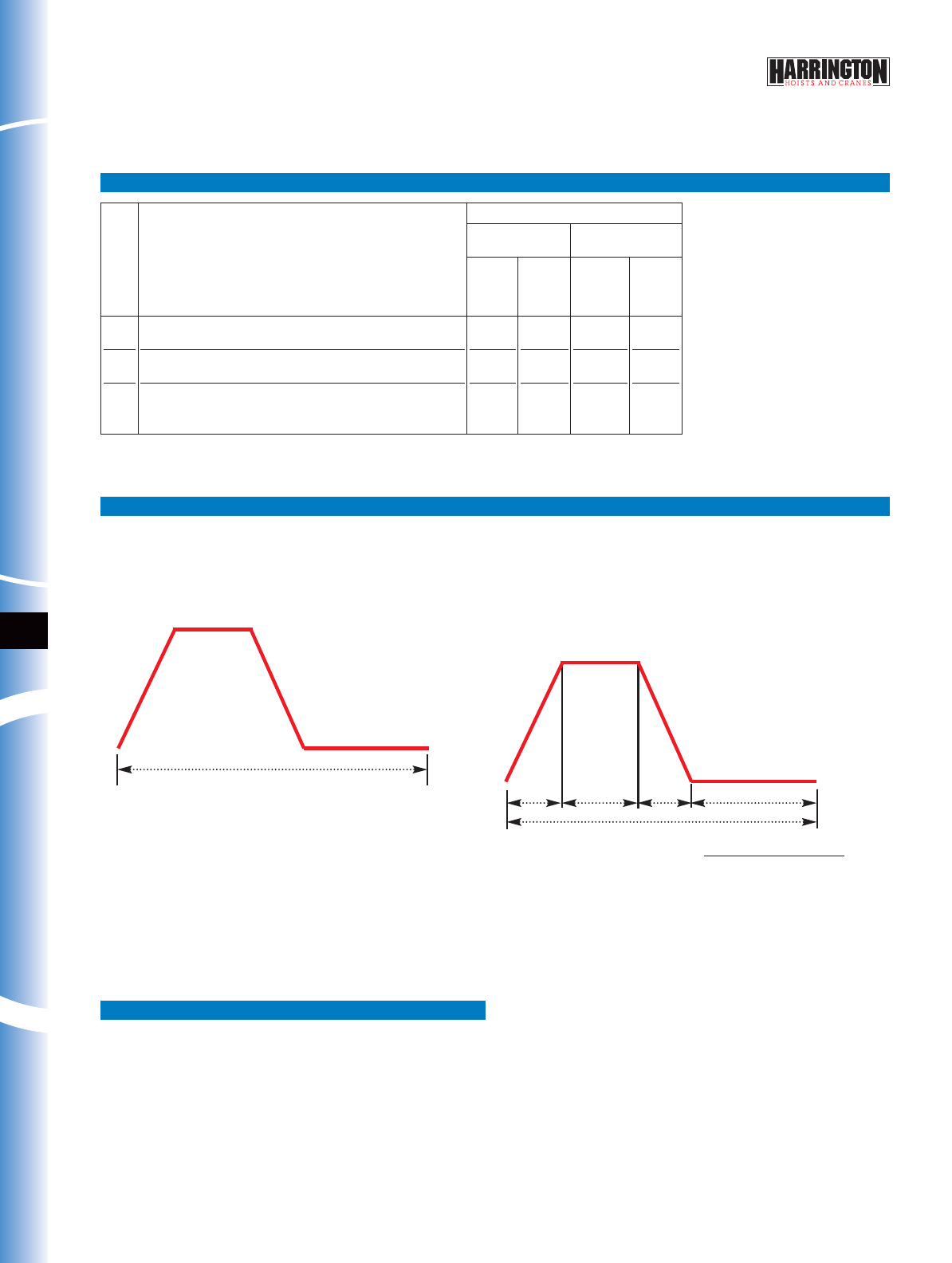

LIFTING MOTOR RATINGS

Short Time Rating

This rating indicates how long the hoist can be operated continuously

at the rated capacity on the cycle below, assuming continued operation

for a short time span.

• Single speed: 60 min

• Dual speed: 30/10 min

Intermittent Rating (Percent ED)

Max. Number of Starts Per Hour

This rating indicates the allowable ratio of motor ON time to motor

OFF time, and starts per hour for a hoist operated continuously

at 63% of rated capacity on the cycle below, assuming continued

operation or repeated starting over a long time span.

NER/ER Lifting Motor Ratings

• Single speed: 60% ED, 360 starts/hr

• Dual speed: 40/20% ED, 120/240 starts/hr

3 sec. stop

3 sec. stop

1 cycle

1m lower

1m lift

Example (single speed): %ED = Motor ON time (t1 + t3

) x 100

T (1 cycle)

(

Where T = 1 cycle (t1 + t2 + t3 + t4) and is not more than 10 minutes.)

stop

stop

T (1 cycle)

lower

t 1

t 2 t 3 t 4

lift

BULLARD

®

AND SHUR-LOC

®

HOOKS

These hooks offer a positive locking latch feature.

Consult Customer Service for full details.