22

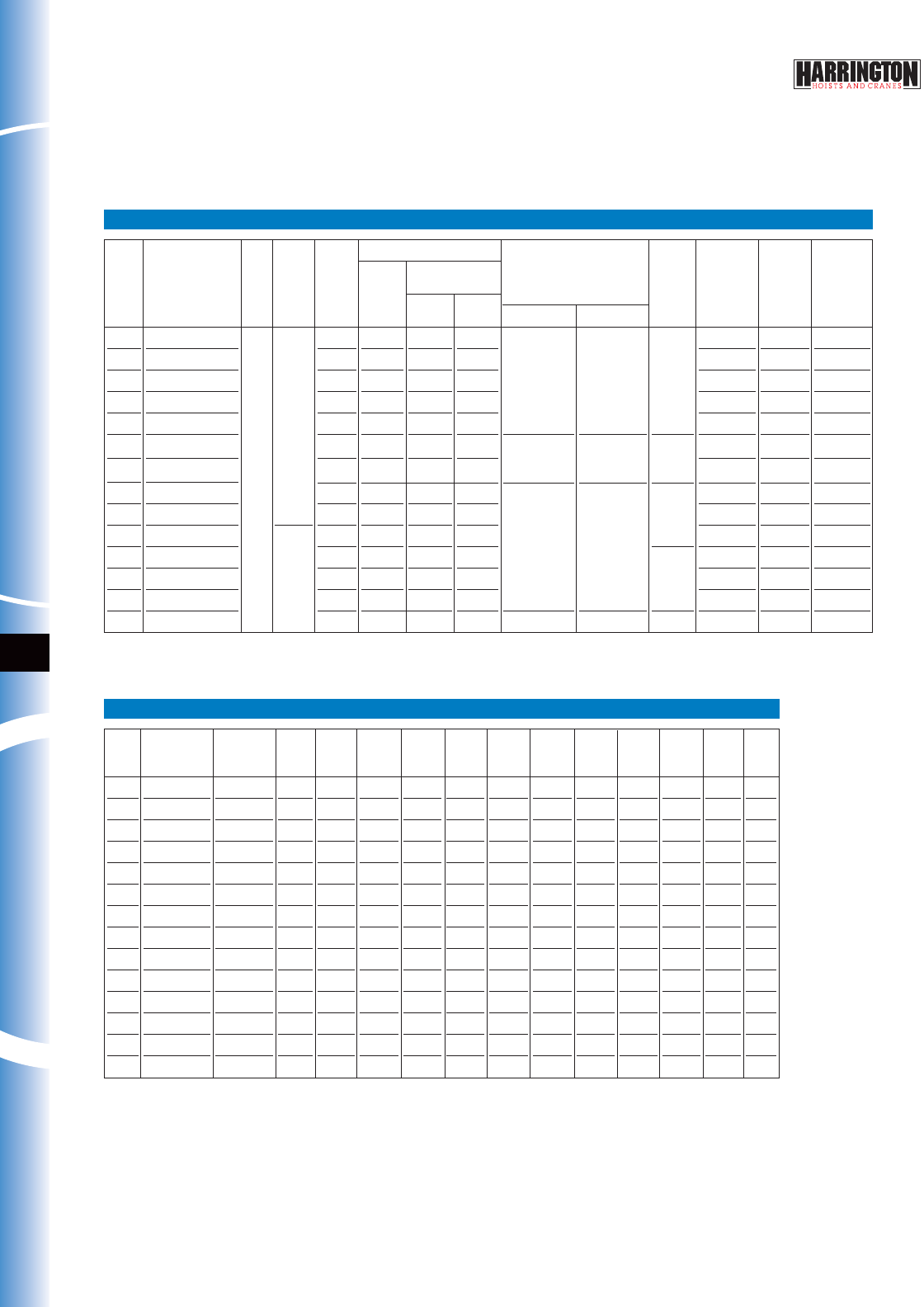

DUAL SPEED HOIST WITH PUSH TROLLEY—DIMENSIONS

Headroom

Cap. Product C a b e g h i j k m n r t

(Tons) Code (in) (in) (in) (in) (in) (in) (in) (in) (in) (in) (in) (in) (in)

1

⁄

8 (N)ERP001HD 15.4 8.0 7.2 1.8 0.9 3.2 2.36 0.7 3.0 1.9 3.3 1.5 0.87

1

⁄4 (N)ERP003SD 15.4 8.0 7.2 1.8 0.9 3.2 2.36 0.7 3.0 1.9 3.3 1.5 0.87

1

⁄4 (N)ERP003HD 16.1 8.0 7.2 1.8 0.9 3.2 2.36 0.7 3.0 1.9 3.3 1.5 0.87

1

⁄2 (N)ERP005LD 15.4 8.0 7.2 1.8 0.9 3.2 2.36 0.7 3.0 1.9 3.3 1.5 0.87

1

⁄2 (N)ERP005SD 16.1 8.0 7.2 1.8 0.9 3.2 2.36 0.7 3.0 1.9 3.3 1.5 0.87

1 (N)ERP010LD 18.1 9.8 9.3 2.2 1.2 4.2 2.80 1.1 3.7 2.2 4.4 2.0 0.98

1 (N)ERP010SD 19.5 9.8 9.3 2.2 1.2 4.2 2.80 1.1 3.7 2.2 4.4 2.0 0.98

1

1

⁄2 (N)ERP015SD 21.9 11.8 11.0 2.7 1.3 5.0 3.35 1.3 4.4 2.8 5.2 2.4 1.26

2 (N)ERP020LD 24.6 11.8 11.0 2.7 1.5 5.0 3.35 1.3 4.4 2.8 5.2 2.4 1.26

2 (N)ERP020SD 28.9 11.8 11.0 2.7 1.5 5.0 3.35 1.3 4.4 2.8 5.2 2.4 1.26

2

1

⁄2 (N)ERP025SD 28.9 12.6 12.8 3.1 1.6 5.8 3.94 1.4 5.3 3.1 6.0 2.7 1.42

3 (N)ERP030LD 30.3 12.6 12.8 3.1 1.7 5.8 3.94 1.4 5.3 3.1 6.0 2.7 1.42

3 (N)ERP030SD 30.3 12.6 12.8 3.1 1.7 5.8 3.94 1.4 5.3 3.1 6.0 2.7 1.42

5 (N)ERP050LD 34.8 11.7 15.7 2.1 1.8 6.7 4.65 1.8 5.7 3.2 7.0 3.5 2.13

Figures in parentheses are data for geared trolley.

*Minimum flange width for curved beam: 1 Ton Push and 1/8 to 1 Ton Geared = 2.87 in.; 3 Ton Push and Geared = 3.50 in.

DUAL SPEED HOIST WITH PUSH OR GEARED TROLLEY—SPECIFICATIONS

Min.* Load Weight

Push Allow. Chain for

Button Radius Dia. Additional

Std. Cord Lifting for (mm) x Net One Foot

Cap. Product Lift L Speed Output @208– @ Curve Chain Fall Weight of Lift

(Tons) Code (ft) (ft) (ft/min) (Hp) 230V 460V Standard Optional (in) Lines (lbs) (lbs)

1

⁄8

(N)ERP(ERG)001HD 58/19 0.6/0.2 2.9/2.4 1.5/1.2 5.0 x 1 90 (108) 0.37 (1.0)

1

⁄4

(N)ERP(ERG)003SD 29/10 0.6/0.2 2.9/2.4 1.5/1.2 4.01 to 8.00 5.0 x 1 90 (108) 0.37 (1.0)

1

⁄4

(N)ERP(ERG)003HD 60/20 1.2/0.4 5.7/5.1 2.9/2.6

2.28 to 4.00 (5.01 to 8.00) 43.3

6.3 x 1 112 (132) 0.57 (1.2)

1

⁄2 (N)ERP(ERG)005LD 14/5 0.6/0.2 2.9/2.4 1.5/1.2

(2.28 to 5.00) OR (51.2)

6.3 x 1 95 (112) 0.57 (1.2)

1

⁄

2 (N)ERP(ERG)005SD 7.5 30/10 1.2/0.4 5.7/5.1 2.9/2.6

8.01 to 12.00

6.3 x 1 112(132) 0.57 (1.2)

1 (N)ERP(ERG)010LD 14/5 1.2/0.4 5.7/5.1 2.9/2.6 5.01 to 8.00 8.0 x 1

128 (139)

0.93 (1.5)

2.28 to 5.00

OR

51.2

1 (N)ERP(ERG)010SD

10

29/10 2.4/0.8 9.1/5.7 4.6/2.9 8.01 to 12.00

8.0 x 1

172 (183)

0.93 (1.5)

1

1

⁄2 (N)ERP(ERG)015SD 20/7 2.4/0.8 9.1/5.7 4.6/2.9 10.0 x 1 203 (214) 1.5 (2.2)

2 (N)ERP(ERG)020LD 15/5 2.4/0.8 9.1/5.7 4.6/2.9 59.1 10.0 x 1 205 (216) 1.5 (2.2)

2 (N)ERP(ERG)020SD 29/10 4.7/1.6 19.6/9.4 9.8/4.7

3.23 to 6.02 6.03 to 12.00

10.0 x 1 322 (333) 1.5 (2.2)

2

1

⁄2 (N)ERP(ERG)025SD 23/8 4.7/1.6 19.6/9.4 9.8/4.7 11.2 x 1 346 (357) 1.9 (2.6)

3 (N)ERP(ERG)030LD 8.2 17/6 4.7/1.6 19.6/9.4 9.8/4.7 66.9 12.5 x 1 355 (366) 2.3 (2.9)

3 (N)ERP(ERG)030SD 23/8 6.2/2.0 24.1/10.6 12.1/5.3 12.5 x 1 375(386) 2.3 (2.9)

5 (N)ERP(ERG)050LD 12/4 4.7/1.6 19.6/9.4 9.8/4.7 3.94 to 7.02 7.03 to 12.00 90.6 11.2 x 2 463 (478) 4.0 (4.6)

Lifting Motor 3 Phase 60 Hz

Rated Current

(amps)

Flange Width

Adjustability

B

(in)

NERP/ERP and NERG/ERG Electric Chain Hoists

With Push and Geared Trolleys