Installation

Installation and Operation 7

Mounting the Pump

• Select a location that allows the operator easy

access to the pump and air controls, sufficient room

to change supply containers, and a secure mount-

ing platform.

• If you are mounting the pump directly on the supply

container, be sure it is positioned so the pump’s

intake tube is no more than 1 in. (25 mm) from the

bottom of the container. Mount the pump to the

cover or other suitable mounting device.

Grounding

Proper grounding is essential to maintaining a safe sys-

tem.

To reduce the risk of static sparking, ground the pump.

Check local electrical codes for detailed grounding

instructions for your area and equipment type. Be sure

the following equipment is properly grounded:

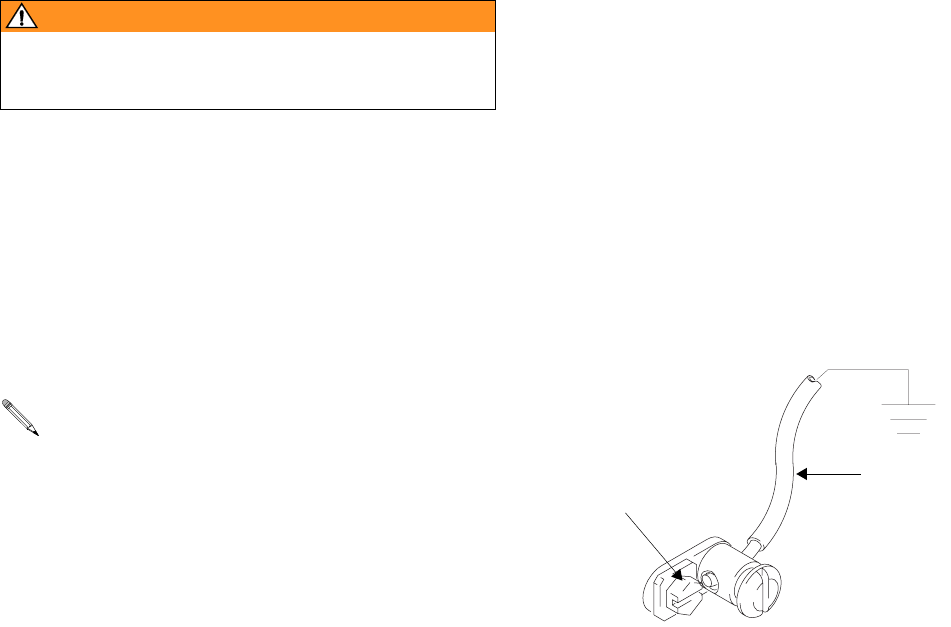

• Pump: See F

IG. 2

• Air and Fluid hoses: Use only electrically conductive

hoses.

• Air compressor: Follow manufacturer’s recommen-

dations.

• Dispensing valve: Obtain grounding through con-

nection to a properly grounded fluid hose and pump.

• Fluid supply container: Follow your local code.

• Object being lubricated: Follow your local code.

• Any pails used when flushing: Use only metal,

grounded pails when flushing. Make firm

metal-to-metal contact between a metal part of the

dispensing valve and the pail. Use the lowest possi-

ble pressure.

• To maintain grounding continuity when flushing or

relieving pressure, always hold a metal part of the

dispensing valve firmly to the side of a metal pail

and then open the dispensing valve.

To maintain grounding continuity when flushing or reliev-

ing pressure, always hold a metal part of the valve firmly

to the side of a grounded metal pail, then trigger the

valve.

To ground the pump, remove the ground screw (Z) and

insert through the eye of the ring terminal at end of

ground wire, (Y). Fasten the ground screw back onto the

pump and tighten securely. Connect the other end of the

ground wire to a true earth ground. See F

IG. 2. To order

a ground wire and clamp order Part No. 222011.

F

IG. 2

WARNING

Mount the pump securely so that it cannot move dur-

ing operation. Failure to do so could result in personal

injury or equipment damage.

To prevent damage to the pump, remove sedi-

ment from the bottom of the container before

installing a pump in an existing container.

Y

Z

TI1052