Page 15

Service

NO USER SERVICEABLE PARTS

INSIDE. Preventive mainte-

nance performed by unauthorized personnel may

result in misplacing of internal wires and compo-

nents which could cause serious hazard.

We

recommend that all tool service be performed by a

Dremel Service Facility.

D.C. motors

The motor in your tool has been engineered for

many hours of dependable service. To maintain peak

efficiency of the motor, we recommend it be exam-

ined every six months. Only a genuine Dremel

replacement motor specially designed for your tool

should be used.

Cleaning

To avoid accidents, always dis-

connect battery pack from tool

before cleaning.

The tool may be cleaned most

effectively with compressed dry air.

Always wear

safety goggles when cleaning tools with com-

pressed air.

Ventilation openings and switch levers must be kept

clean and free of foreign matter. Do not attempt to

clean by inserting pointed objects through opening.

Certain cleaning agents and

solvents damage plastic parts.

Some of these are: gasoline, carbon tetrachloride,

chlorinated cleaning solvents, ammonia and house-

hold detergents that contain ammonia.

!

WARNING

Maintenance

!

WARNING

!

CAUTION

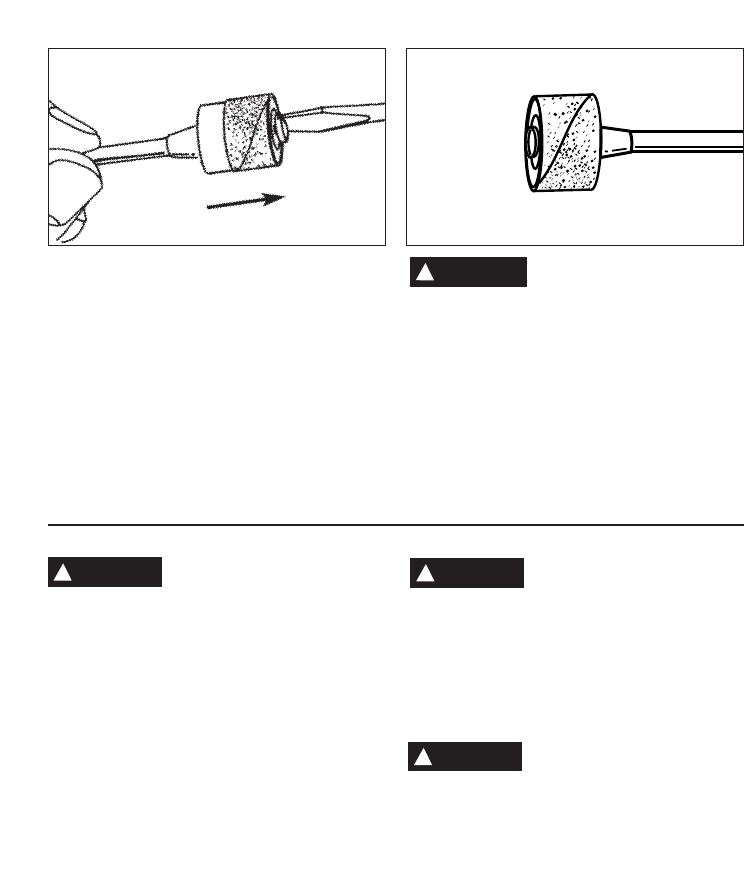

To replace a band on the Drum Sander, loosen the

screw without removing it to contract the drum

then slide the old band off. Slide the new sanding

band on and then expand the drum by tightening

the screw once again.

Before each use, check to

make certain that all compo-

nents are assembled to accessory shank and that

the drum is sufficiently expanded to secure the

band during use.

If sanding band is loose on the

drum during operation it may “fly” off and strike

you or bystanders.

WARNING

!