30

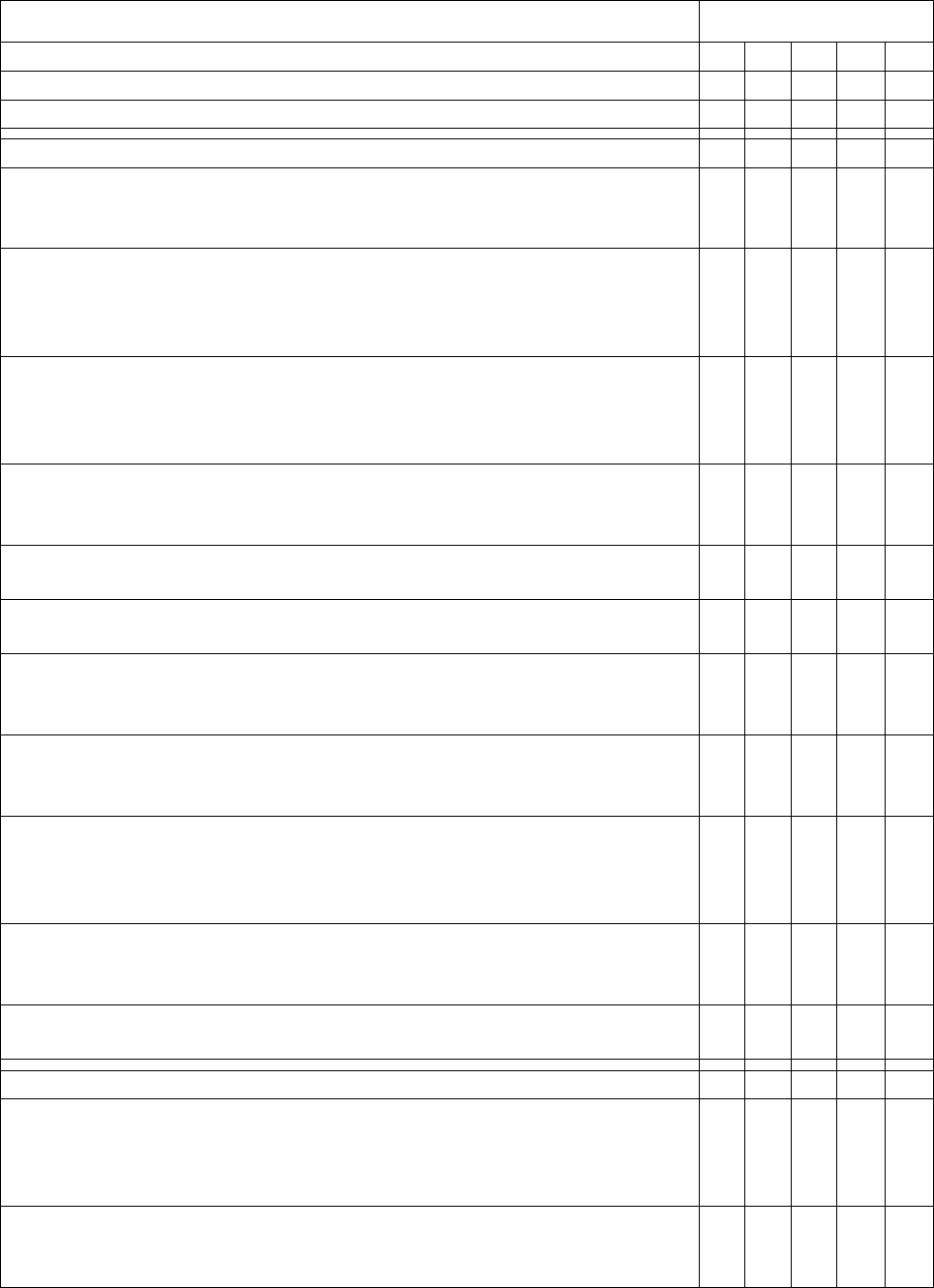

8.1. Maintenance Schedule

Inspection, Mandatory Work Inspection Period

10 25 50 100 200

Engine

As per ROTAX Manual attached.

Engine Compartment

Engine Attachment

Check integrity of construction with special care for welds, fixing points,

silent blocks, bushings. Surface finish quality.

x

Bolted Connections

Check surface quality of bolted connections and bearing surfaces.

Securing, tightening. Tighten and re-secure if necessary, Replace self

locking nuts, split pins and securing wires.

x

Silent Blocks

Check elasticity of engine bearing, integrity of rubber blocks, degree of

permanent deformation. Replace silent blocks if necessary, tighten,

secure.

x

Oil, Water and Fuel Hoses

Check surface integrity, liquid leakage, quality of connections, protection

against oscillating parts and exhausts. Replace if necessary.

x

Working Liquids

Check level, refill keeping instruction of engine manufacturer.

x

Coolers

Check integrity, sealing, purity.

x

Controls

Check control forces, free play, hinges, end stops adjustment, self-

locking. Adjust, secure.

x

Exhausts

Check integrity, sealing, corrosion degree, springs quality and prestress.

Grease ball connections.

x

Carburetors

Check surface quality, controls adjustment, quality of elastic connection

flange – integrity, sealing. Replace flange if material degradations or

surface cracks appear.

x

Electric Installations

Check quality, integrity and purity if cables, contacts, welds, bunched

cable supports and bushings. Check gauges and senders connections.

x

Propeller Attachment

Check quality of bolts, tightening moments, securing.

x

Cockpit

Control Sticks

Check free movement in longitudinal and cross direction, clearance fits,

end stops adjustment, securing. Replace pins or bolts if worn-out, grease,

secure.

x

Rudder Control

Check integrity of pedals with special care for surface cracks near welds.

Full and free movement right and left (raise nose wheel off ground), end

x