10. PROGRAMMING PROCEDURES

10.2 PLU DATA SETTING

10- 6

Pressing the key instead of the key proceeds to the next menu. Pressing the

key returns to the preceding menu.

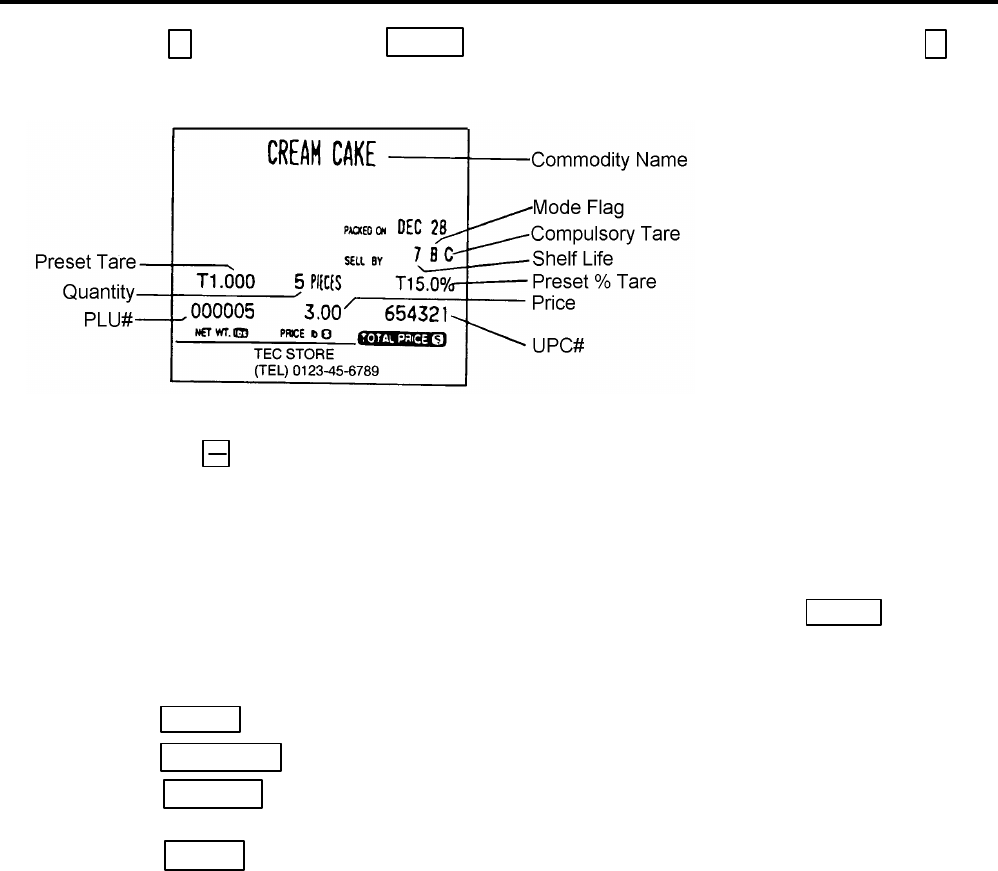

Verification label of PLU data

ENTER

NOTES:

1. A UPC code is made up of a combination of an entered code and an AUTO CODE. Be sure to

attach some characters to the end of the AUTO CODE, or all entered codes will be ignored

and an AUTO CODE will become a UPC code (see ex. 1).

ex. 1) enter code: 456 ex. 2) enter code: 4567 ex. 3) enter code: 123456

AUTO CODE: 123- - - AUTO CODE: 123- - - AUTO CODE: 987

code#: 123456 code#: 123567 code#: 987

2. When there is no area to store PLU data, an error occurs when pressing the key.

3. Changing a PLU # to the number to which other PLU data is already set will result in an error.

4. Unit price flag may be selected as follows:

1) In case of lb scale

a. key : $ per lb

b. key : $ per 1/2 lb

c. key : $ per 1/4 lb

2) In case of kg scale

a. key : $ per 100 g or Kg

5. Tare limit should be a multiple of 1, up to 4.00 lb for US type and a multiple of 5, up to 2.000 Kg for

CA type.

6. Safe handling instructions

Safe handling instructions is printed when the following label format # is selected.

<Format #> <Number of ingredient lines printed>

57-mm wide labels

13/63: POS-ING 18 lines 5

15/65: POS-ING 38 lines 25

16/66: POS-ING 37 lines 24

23/73: NET-ING 18 lines 5

25/75: NET-ING 38 lines 25

26/76: NET-ING 38 lines 25

33/83: B.C.-ING 18 lines 5

35/85: B.C.-ING 38 lines 25

36/86: B.C.-ING 38 lines 25

44/94: FSP-ING 8 lines 0

48: Variale length Variable

41-43: Free Format -

49: Rotation Label 8

80-mm wide labels

23-73: NET-ING 22 lines 9

# 44/94: FSP-ING 8 lines 0

# 47/97: 960-ING 8 lines 0

*The normal safe handling instructions is equal to 13 lines of type-0 ingredients in size and wide one

is equal to 8 lines of type-1 ingredients in size as marked #.

INSERT 1

DELETE (A) 1/2

RETURN 1/4

INSERT 1

ENTER

(W: Weigh, F: Fix, B: By-count)

(C: Compulsory, Blank: Not compulsory)