8

4.1. BASIC AND ZERO/SPAN VALVE OPTION CONFIGURATIONS

CAUTION

Sample and calibration gases should only come into contact with PTFE

(Teflon), FEP, glass, stainless steel or brass.

Do NOT operate without first removing dust plugs from rear panel fixtures.

NOTE

To prevent dust from entering the gas flow channels, your analyzer was shipped with small

plugs inserted into each of the pneumatic fittings on the back panel. Remove these dust

plugs and store for future use before proceeding.

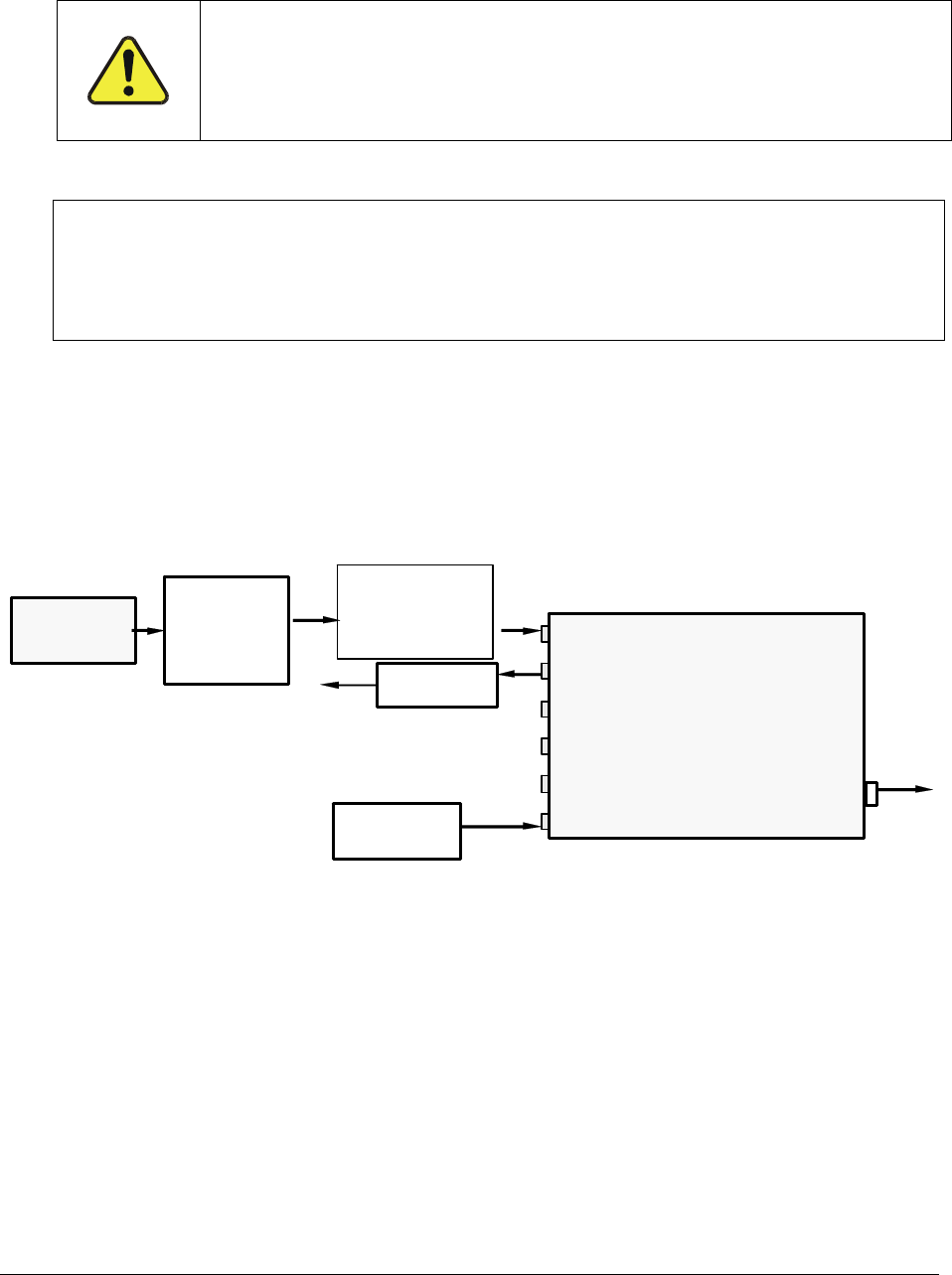

Figure 4-2 illustrates the most common configuration for gas supply and exhaust lines to

the Model T360U Analyzer. Figure 4-3 illustrates the pneumatic connections for optional

configuratio

n with zero/span valves. Table 4-1 describes the pneumatic ports.

Note that the flowmeter

could also be configured upstream of the instrument. Since most

flowmeters are calibrated at ambient pressure, ensure that the flow going through the flow

meter is at ambient pressure, when it is placed upstream.

Needle valve,

set flow to 800

cc/min (+/- 10%)

Chassis

Sam

p

l

e

Zero

Exhaus

t

Vent Span

Pressure Span

To Pur

g

e

Sample/

Cal gas

From Purge

Flowmeter

Pressure

regulator (set

to 10-15 psig

output)

10-30 psig

CO2 free

g

as

Figure 4-2. Pneumatic Connections–Basic Configuration