26

IX. SET UP & ADJUSTMENT

I. WHEEL LOCKS

Note: Use a torque setting of 100 in.-lbs. when

setting up wheel locks.

1. Low-Mount Scissor Wheel Locks:

Loosen screws on top clamp. Slide

assembly toward rear wheel until clamp

embeds into tire to prevent wheel move-

ment, when in locked position. Adjust

angle position and tighten screws.

Using wheel locks for braking is danger-

ous. Use wheel locks for parking ONLY.

When properly adjusted, wheel locks pre-

vent the rear wheels from turning when

the chair is parked. Always adjust the

wheel locks after making any changes to

the rear axle sleeve position. Wheel locks

should be embedded into the tires to pre-

vent wheel movement.

2. High-Mount Push-to-Lock or Pull-to-

Lock Wheel Locks:

To adjust push-to-lock toggle type locks that

mount with a split clamp, loosen the screws

on the top of each clamp. Using a 3/16”

Allen wrench, turn one of the screws coun-

terclockwise one-quarter turn. Repeat the

same process with the second of the two

screws. Alternately loosen the screws (two

turns each) until both screws are removed.

Slide clamp toward the rear wheel until the

wheel lock is embedded into the tire to

prevent wheel movement (when in the

locked position). Tighten screws. Some

adjustments to the wheel lock position can

be accomplished without moving the clamp.

To adjust, loosen the two socket-head cap

screws on the top of the clamp. Slide the

mounting bar forward or backward and

rotate it to the correct angle position. The

wheel lock should embed into the tire to

prevent wheel movement when in the

locked position. Tighten screws.

Note: High-mount push-to-lock require frame

modifications for use on your Shadow Rigid.

▲

!

WARNINGS

IX. SET UP & ADJUSTMENT

J. FOOTREST

Adjust height by removing bolts and sliding

footrest up or down to desired position.

Replace bolts.

Note: Footrest adjusts in 3/4” increments. Keep

footrest 1”-2” above the ground. Use a torque set-

ting of 100 in./lbs. when adjusting footplate.

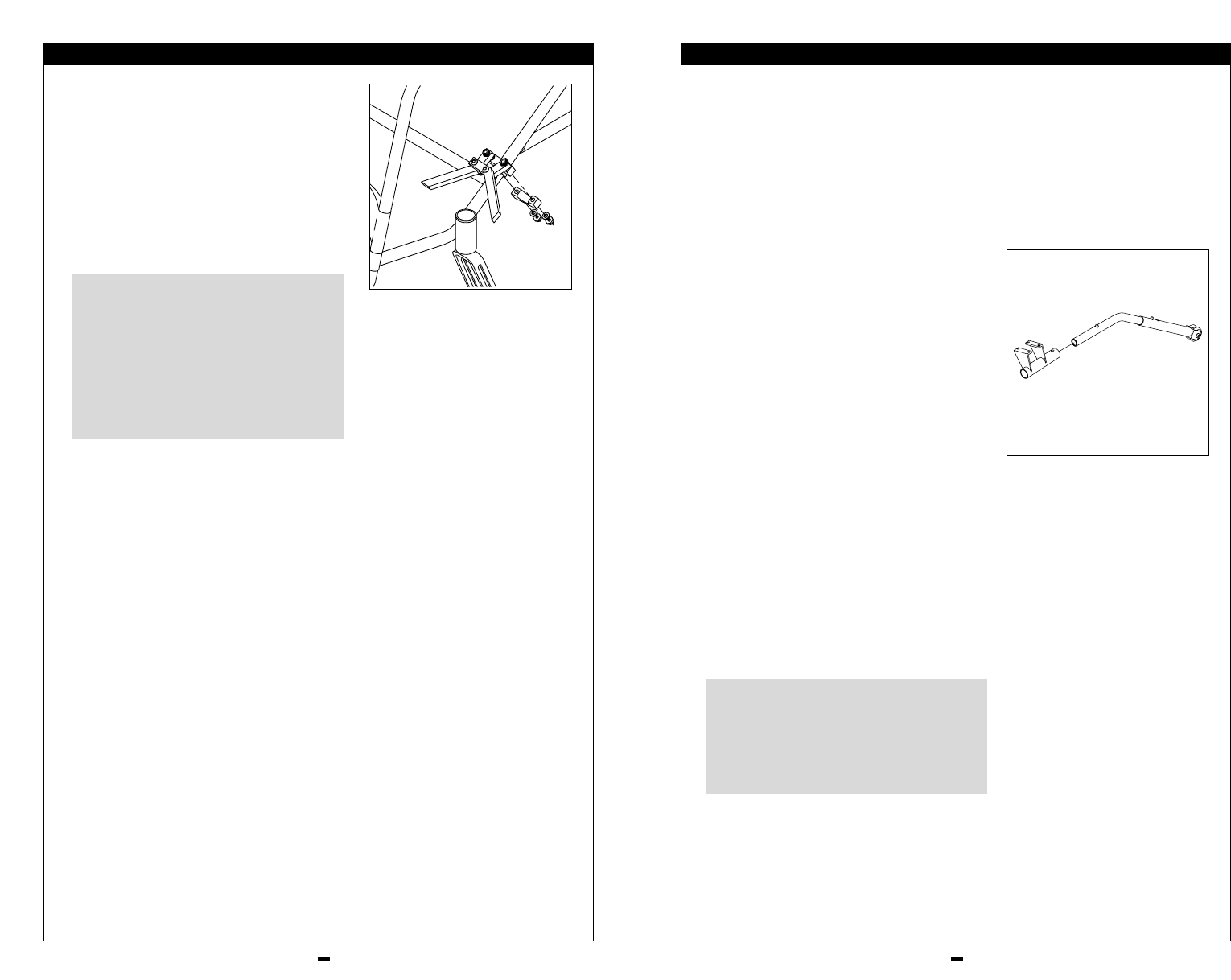

K. ANTI-TIP TUBES (Optional)

Note: Use a torque setting of 100 in.-lbs. when set-

ting up the anti-tip tubes.

Remove anti-tip tubes from anti-tip

receivers. Remove button head bolts from

camber tube mounting brackets. Install

anti-tip receiver on the underside of the

camber tube with the long part of the tube

facing rearward. Use the longer screw

supplied with the anti-tips and reinstall

the camber tube and mounting brackets.

Insert the anti-tip tube into the receiver.

Turn the anti-tip tube down until release

pin is through the receiver mounting hole.

Insert second anti-tip tube the same way.

CAUTION:To allow the anti-tip tubes to func-

tion properly there must be a 1 1/2” to 2”

clearance from the anti-tip wheel to the

ground. To maintain this clearance an adjust-

ment in the positioning of the anti-tip tube

should be made to correspond with any

change in seat height.

Failure to adjust anti-tip tubes correctly can

result in injury to the rider. Anti-tip tubes

are available from your local authorized

Quickie supplier. Quickie Designs recom-

mends anti-tip tubes for wheelchairs.

▲

!

WARNINGS

27