MVC-90L PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #1 (11/01/05) — PAGE 19

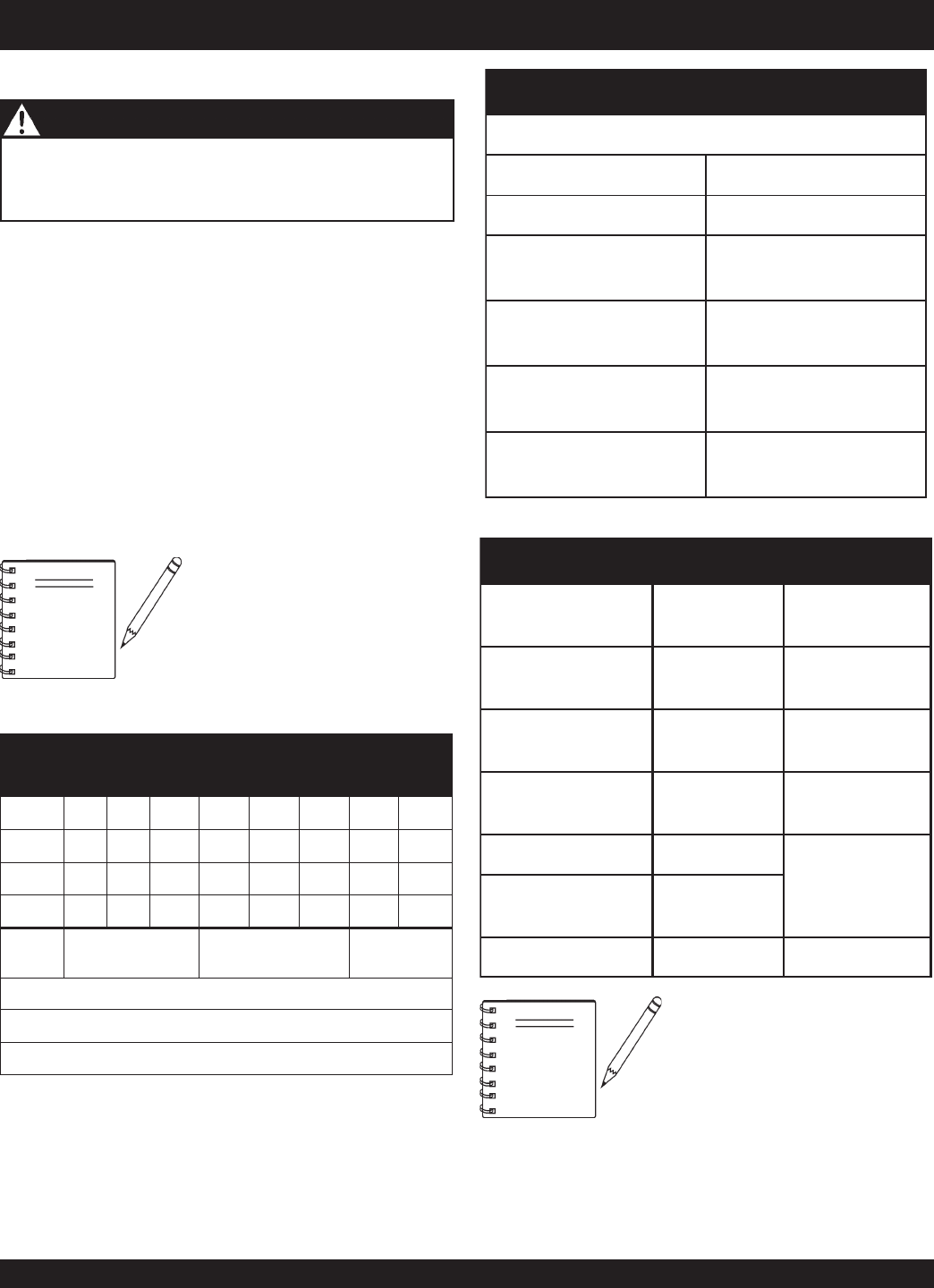

Inspection and Maintenance Service Tables.

To make sure your plate compactor is always in good working

condition before using, carry out the maintenance inspection in

accordance with Tables 5 through 7.

These inspection intervals are for

operation under normal conditions.

Adjust your inspection intervals

based on the number hours plate

compactor is in use, and particular

working conditions.

MVC-90L PLATE COMPACTOR — MAINTENANCE

NOITCEPSNIENIGNE.6ELBAT

)launaMenignEetarepesees,sliatedroF(

metIkcehCnoitarepOfosruoH

egakaeLliOroleuF)yliaD(sruoH8yrevE

sdaerhTgninetsaF

ssenthgiT

)yliaD(sruoH8yrevE

h

sinelpeR/kcehC

liOenignE

)yliaD(sruoH8yrevE

liOenignEecalpeR

,sruoh02tsriF

sruoh001yreveneht

ehtnaelC/kcehC

renaelCriA

sruoh05yrevE

EUQROTGNINETHGIT.5ELBAT

retemaiD)mc/gk.ni(

lairetaM

mm6 mm8 mm01 mm21 mm41 mm61 mm81 mm02

T4 07 051 003 005 057 001,1 004,1 000,2

T8-6 001 052 005 008 003,1 000,2 007,2 008,3

T11 051 004 008 002,1 000,2 009,2 002,4 006,5

*

001

)mm6(

053~003

)mm8(

007~056

)mm01(

)munimulafositrap-retnuocesacnI(*

.wercsdna,tlobhcaenodekramsilairetamfoytilauqdnalairetaM

dednahthgirllaeraenihcamsihthtiwesunisdaerhT:etoN

Fuel piping and connections should

be replaced every 2 years.

Daily Service

z

Check for leakage of fuel or oil.

z

Remove soil and clean the bottom of compaction plate.

z

Check engine oil.

z

Check for loose screws including tightness. See Table 5

below (tightening torque ), for retightening:

H09-CVM.7ELBATNOITCEPSNIENIHCAM

METI

FOSRUOH

NOITAREPO

SKRAMER

straPdegamaDsruoh8yrevE

erofeBkcehC

noitarepOyliaD

swercStsoLroesooLsruoh8yrevE

erofeBkcehC

noitarepOyliaD

gnillortnoCfonoitcnuF

traPmetsyS

sruoh8yrevE

erofeBkcehC

noitarepOyliaD

kcehCliOr

otarbiVsruoh001yrevE

12egaPeeS

liOrotarbiV

tnemecalpeR

sruoh003yrevE

kcehChctulC&tleb-Vsruoh002yrevE22egaPeeS

CAUTION - General Maintenance Safety

Maintenance

Inspection and other services should

always

be carried out

on hard and level ground with the engine shutdown.

NOTE

NOTE