MVC-90L PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #1 (11/01/05) — PAGE 15

MVC-90L PLATE COMPACTOR — INSPECTION

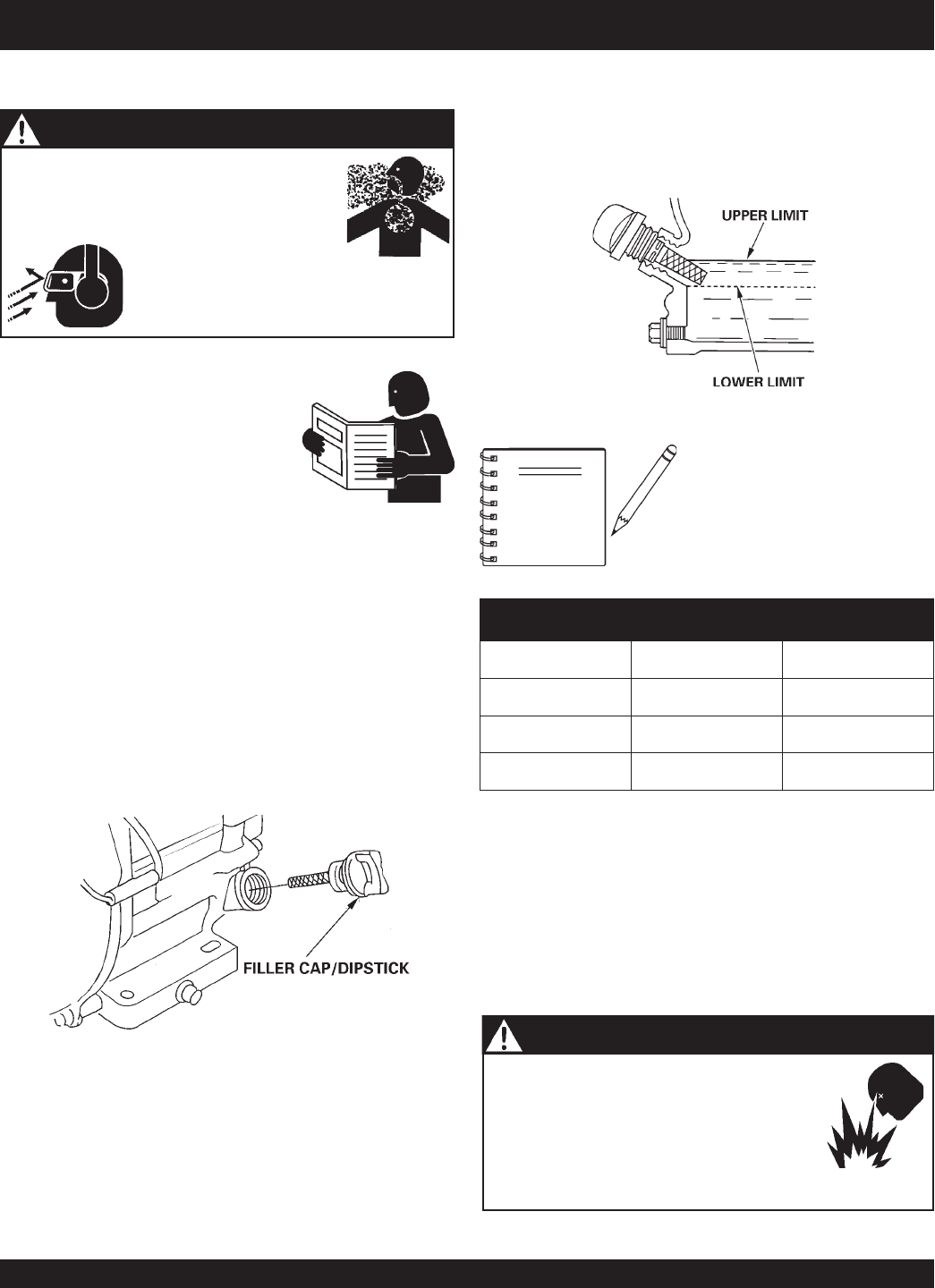

3. Insert and remove the dipstick without screwing it into the

filler neck. Check the oil level shown on the dipstick.

4. If the oil level is low (Figure 6), fill to the edge of the oil filler

hole with the recommended oil type (Table 4). Maximum oil

capacity is 400 cc.

Figure 6. Engine Oil Dipstick

epyTliO.4elbaT

nosaeS erutarepmeT epyTliO

remmuS rehgiHroC°52 03-W01EAS

llaF/gnirpS C°01~C°52 02/03-W01EAS

retniW rewoLroC°0 01-W01EAS

The Oil Alert system will

automatically stop the engine

before the engine falls below safe

limits. Always be sure to check the

engine oil level prior to starting

the engine.

CAUTION - General Safety Precautions

ALWAYS wear approved eye and hearing

protection before operating the compactor.

NEVER operate the compactor in a confined

area or enclosed area structure that does not

provide ample

free flow of air

.

Engine Oil Check

1. To check the engine oil level, place the plate compactor on

secure level ground with the engine stopped.

2. Remove the filler cap/dipstick from the engine oil filler hole

(Figure 5) and wipe it clean.

Before Starting:

Fuel Check:

1. Remove the gasoline cap located on top of fuel tank.

2. Visually inspect to see if the fuel level is low. If fuel is low,

replenish with unleaded fuel.

3. When refueling, be sure to use a strainer for filtration. DO NOT

top-off fuel. Wipe up any spilled fuel

immediately!

Explosive Fuel

Gasoline is extremely flammable, and its

vapors can cause an explosion if ignited. DO

NOT start the engine near spilled fuel or

combustible fluids. DO NOT smoke while

refueling. DO NOT attempt to refuel the pump

if the engine is

hot!

or

running

.

WARNING - Explosive Fuel

Figure 5. Engine Oil Dipstick

1. Read safety instructions at the

beginning of manual.

2. Remove dirt and dust, particularly

in the engine cooling air inlet,

carburetor and air cleaner.

3. Check the air filter for dirt and dust.

If air filter is dirty, clean or replace the air filter with a new

one as required.

4. Check carburetor for external dirt and dust. Clean with dry

compressed air.

5. Check fastening nuts and bolts for tightness.

NOTE