20

MAINTENANCE

WARNING

• Never perform maintenance on the hoist while it is

supporting a load.

• Before performing maintenance, tag controls:

DANGER - DO NOT OPERATE -

EQUIPMENT BEING REPAIRED.

• Only allow personnel trained in operation and service of this

hoist to perform maintenance.

• After performing any maintenance on the hoist dynamically

test the hoist to 100% of its rated capacity, in accordance with

ASME B30.16 standards, before returning hoist to service.

Testing to more than 100% of rated capacity is required to set

overload device and may be required to comply with

standards and regulations set forth in areas outside the USA.

• Shut off air system and depressurize air lines before

performing any maintenance.

Proper use, inspections and maintenance increase the life and

usefulness of your Ingersoll-Rand equipment. During assembly,

lubricate gears, bearings and shafts with applicable lubricants.

Use of a thread locking compound and/or thread lubricant on

capscrew and nut threaded areas helps prevent corrosion of

components.

Maintenance Intervals

The Maintenance Interval Chart below is based on intermittent

operation of equipment for eight hours each day, five days per

week. If the equipment is in operation for more than eight hours a

day or is operated in severe applications or environments, more

frequent maintenance should be performed.

INTERVAL

MAINTENANCE CHECK

Start of each shift

Make a thorough visual inspection of the

hoist for damage. Do not operate the hoist if

damage is found.

Operate in both directions. Hoist must

operate smoothly without sticking, binding

or abnormal noises.

Check the operation of the brake.

Quarterly

Remove, clean or replace muffler in top of

gear housing.

Yearly

Inspect the hoist gearing, shafts and bearings

for damage or wear. Repair or replace as

necessary.

Check all of the supporting members,

including the trolley if used. Repair or

replace as required.

Adjustments

Brake

No brake adjustment is required.

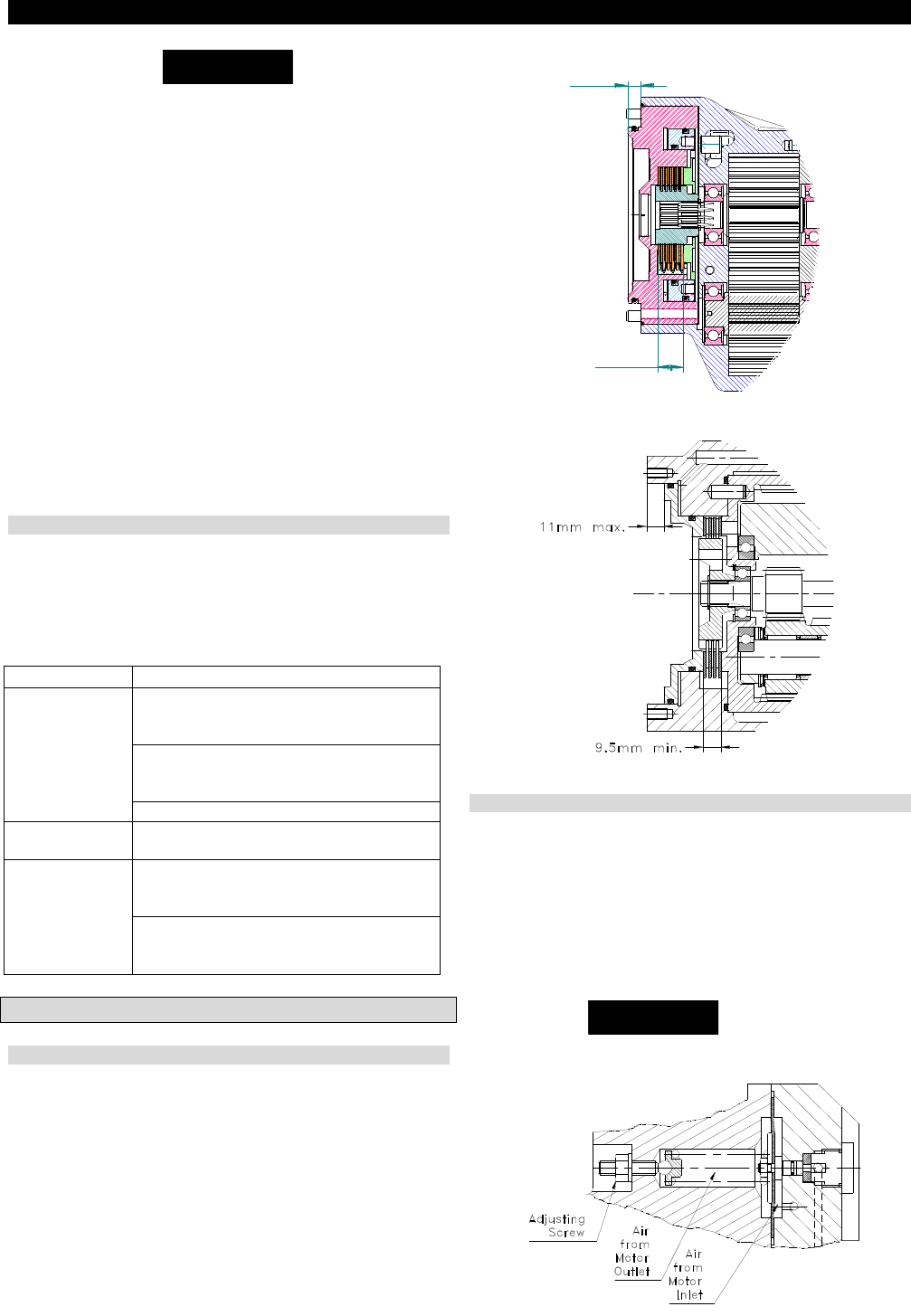

Annual Maintenance is limited to:

1. A general cleaning.

2. The friction discs have a 0.2 mm (0.079 in.) deep groove on

each side. Replace the friction discs if the grooves are no longer

visible. Refer to Dwg. D6440775 or D4120242.

3. Measure total brake and steel plate stack up. Check that

measurement is not less than minimum shown.

LC2A015S and LC2A030D Hoists

(D6440775)

LCA030S TO LCA250Q Hoists

(Dwg. D4120242)

Overload Device

1. Connect the hoist to the air supply.

2. Release the locknut and turn the adjustment screw in order to

increase or decrease the SWL (increase the SWL by

tightening the adjustment screw). The adjustment must be

made for an overload of 20% maximum of the SWL.

3. Tighten the locknut securing the adjustment screw.

4. Check hoist operation at rated load. If necessary repeat the

adjustment.

NOTICE

OTICE

• Do not change factory settings unless hoist is tested and

recertified at an authorized repair facility.

(Dwg. D4120413)

A

A

B

D6440775

14,5 mini

7,5 mini