INF200-MAN P. 5

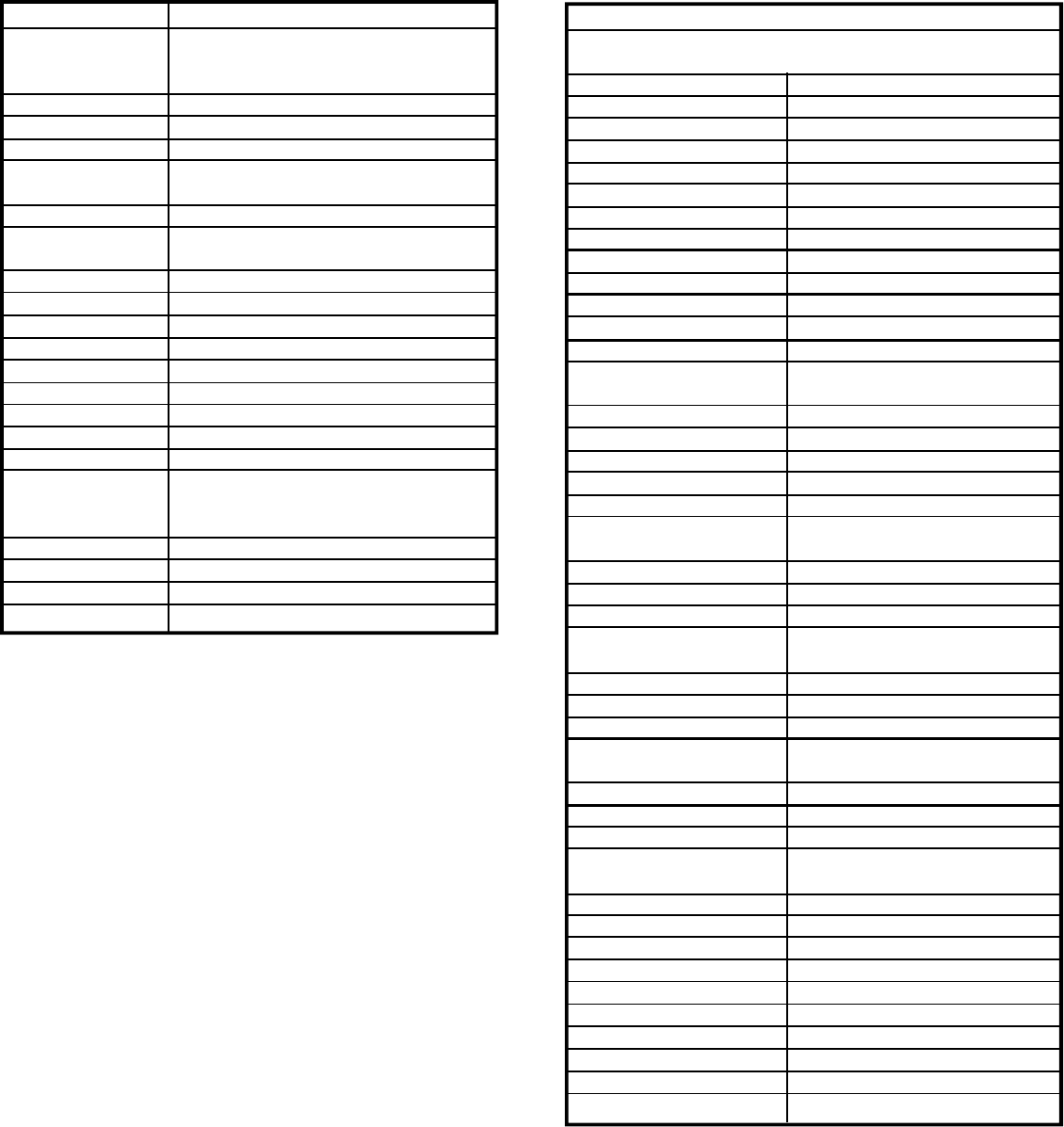

S p e c i f i c a t i o n s

*Laser is offset 1 -2 cm (0.5”) above center of target spot.

**Battery life will vary based on backlight and laser storage.

Tro u b l e s h o o t i n g

No display or erratic display: check the battery for proper voltage and

tight contact at the battery clip. Ensure the unit is at the specified

operating temperature.

Constant or spurious over-load (OL) display: check battery voltage.

Check for electromagnetic interference (EMI). To check for EMI, move

the unit to an open area, away from high voltage and radio or radar

transmitting sources.

Errornous temperature readings: inspect the infrared lens for blockage

or contamination. Follow cleaning instructions. Check battery for proper

voltage and tight fit in the battery clip.

Emissivity Va l u e s

*Emissivity various with purity.

Temperature range 0 to 788˚F (-20 to 420˚C)

Accuracy ±2% of rdg. or ±3˚F (±2˚C), whichever is greater @

73 ±9˚F (23 ±5˚C) ambient operating temperature

and a known blackbody emissivity

Repeatability ±1% of rdg. or ±2˚F (±1˚C) whichever is greater

Response time 500 m sec. (95% response)

Special response 7-18 microns nominal thermopile detector

MIN/MAX/

▲

T/AVG X

temperature

Recall last reading X

HI or LO X

audible / visible alarm

LCD backlight X

Laser (class 2 output) X

Emissivity .30 - 1.00 digitally adjustable

Temperature display ˚F or ˚C (selectable) 3 digit LCD

Display resolution 1˚F or 1˚C in all modes

Ambient operating range 32 to 120˚F (0 to 50˚C)

Relative humidity 10 - 95% RH noncodensing @ up to 85˚F (30˚C)

Storage temperature -13 to 158˚F (-25 to 70˚C) without battery

Power 9V Alkaline battery

Battery life (Alkaline) All models 50 hrs. (backlight not used)*

Enhanced laser sighting model 16 hrs.

Laser used 50%, backlight used 50%**

Dimensions 5.4” x 1.6” x 7.7” (137 mm x 41 mm x 196 mm)

Weight 9.5 oz. (270 gm)

Accessories Water resistant hard case and manual

Distance spot ratio 8 to 1

Typical Emissivity Values - Metals

Surface Emissivity

Iron and Steel

Cast iron (polished) 0.2

Cast iron (turned at 100˚C) 0.45

Cast iron (turned at 1000˚C) 0.6 to 0.7

Steel (ground sheet) 0.6

Mild steel 0.3 to 0.5

Steel plate (oxidized) 0.9

Iron plate (rusted) 0.7 to 0.85

Cast iron (rough) rusted 0.95

Rough ingot iron 0.9

Molten cast iron 0.3

Molten mild steel 0.3 to 0.4

Stainless steel (polished) 0.1

Stainless steel (various) 0.2 to 0.6

Aluminum

Polished aluminum 0.1*

Aluminum (heavily oxidized) 0.25

Aluminum oxide at 260˚C 0.6

Aluminum oxide at 800˚C 0.3

Aluminum alloys, various 0.1 to 0.25

Brass

Brass (polished) 0.1*

Brass (roughened surface) 0.2

Brass (oxidized) 0.6

Copper

Copper (polished) 0.1*

Copper plate (oxidized) 0.8

Molten copper 0.15

Lead

Lead (pure) 0.1*

Lead (oxidized at 25˚C) 0.3

Lead (oxidized, heated to 200˚C) 0.6

Nickel and its alloys

Nickel (pure) 0.1*

Nickel plate (oxidized) 0.4 to 0.5

Nichrome 0.7

Nichrome (oxidized) 0.95

Zinc (oxidized) 0.1*

Galvanized iron 0.3

Tin-plated steel 0.1*

Gold (polished) 0.1*

Silver (polished) 0.1*

Chromium (polished) 0.1*