Maintenance

11

Maintenance Inspection Checklist

Regular cleaning will reveal loose or worn parts, enhance smooth operation and extend

the life expectancy of the lift.

Maintenance

10

Lubrication & Casters

The lift is designed for minimum maintenance;

however, a six (6) months check and lubrication

should ensure continued safety and reliability.

The casters MUST swivel and roll smoothly. A white

grease (waterproof auto lubricant) may be applied to

the ball bearing swivel of the casters once a year.

Apply more frequently if the casters are exposed to

extreme moist conditions.

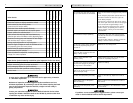

Refer to Figure 1 for lubrication points. Lubricate all

pivot points. Wipe all excess lubricant from lift surface.

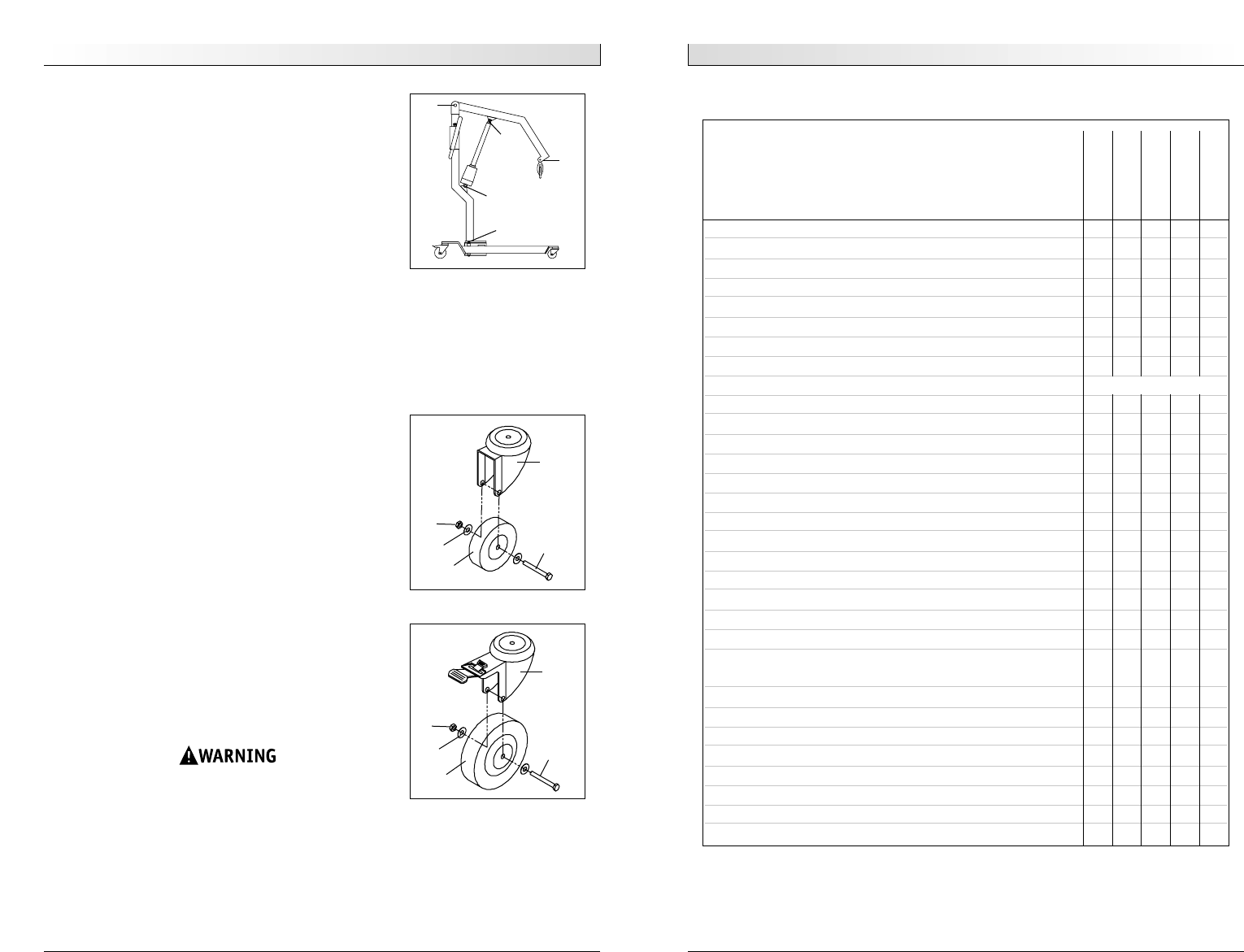

Cleaning of Casters

1. Place the lift on its side.

2. Remove the bolt and locknut that secure the

existing front caster assembly to the fork.

3. Remove all debris and clean any dust.

NOTE– For the front caster, examine and replace the

existing washer if worn. The front caster assem-

bly consists of two (2) washers and a caster in

between. The caster will fall out between the

two (2) washers (Figures 2 & 3).

4. Position the front caster in the assembly and

tighten up the bolt and locknut.

5. Line up the mounting holes in the new front

caster assembly and the fork

6. Install the bolt through the fork and caster

assembly and tighten securely with the locknut.

Annual Inspection

The HPL600 and its accessories must be inspected

annually.

The HPL600 and its accessories must be serviced

every 12 months as a minimum requirement.

As part of the annual inspection, an annual load test

with the safe working load must be performed on the

HPL600 as required for CE mark maintenance.

1. Carry Bar

2. Boom Mounting Bracket

3. Boom / Mast Mount

4. Mast Mounting Bracket

5. Leg Pivots

1. Locknut

2. Washer

3. Caster wheel

4. Bolt

5. Fork

Figure 1

Figure 2 Front Caster

Figure 3 Rear Caster

1

2

3

4

5

5

4

3

2

1

5

4

3

2

1

Lift Device

Inspect for missing hardware or broken pieces ✓✓ ✓

Battery recharge ✓✓

Slings and Hardware

Check all sling attachments for sign of wear ✓

Inspect sling material for wear or deterioration ✓

Inspect sling straps for wear ✓

Inspect for any defect or loose threads in stitched areas ✓

Clean sling as indicated on the tag ✓

The Caster Base

Inspect for missing hardware ✓✓

Base opens/closes with ease ✓✓

Inspect casters and axle bolts for tightness ✓✓

Inspect caster for smooth swivel and roll ✓✓

Clean casters ✓

The Mast

Mast MUST be securely assembled to boom ✓✓

Inspect for cracks or deflections ✓✓

The Boom

Check all hardware and swivel bar supports ✓✓

Inspect for cracks or deflections ✓✓

Inspect bolted joints of boom for wear ✓✓

Inspect to ensure that the boom is centered between ✓✓

the base legs.

Check the bolt/hooks for wear or damage ✓✓

Check sling hooks for wear or deflections ✓✓

The Manual/Hydraulic/Electric Actuator Assembly

Inspect hardware on mast and boom ✓✓

Check for wear or deterioration ✓✓

Cycle to ensure smooth quiet operation ✓✓

Cleaning

Cleaning of the lifter ✓✓

TO BE INSPECTED BY USER:

Initially

Before each use

Every 2 months

Every 4 months

Every year

When necessary