20

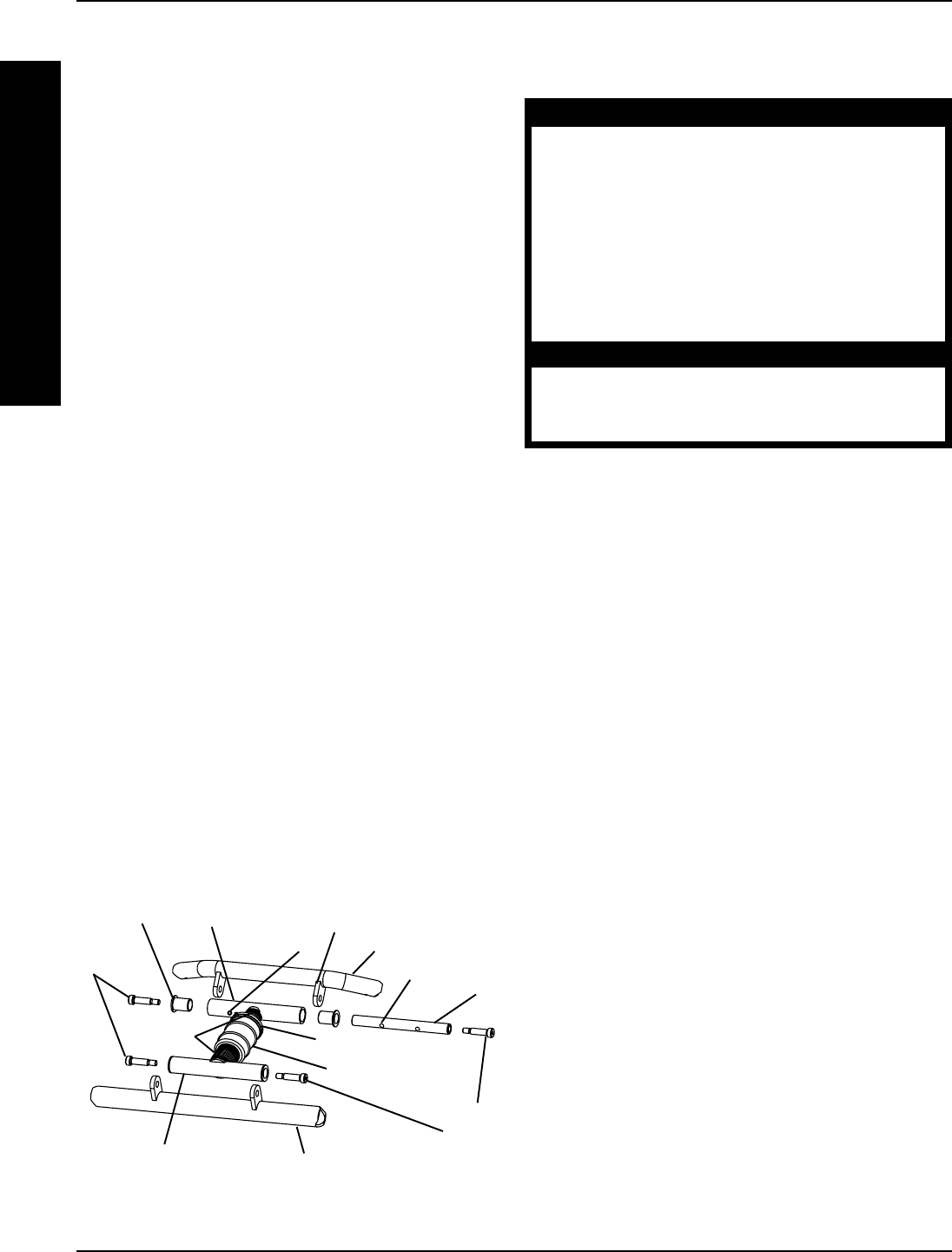

REPLACING TURNBUCKLE ASSEMBLY

- A-6/A6-S ONLY (FIGURE 5)

NOTE: The turnbuckle assembly consists of the inside

screw, turnbuckle, outside screw, flanges and rods. If

the turnbuckle assembly becomes disassembled, refer

to FIGURE 5.

1. Carefully tip the wheelchair back so the back canes rest

on the ground.

2. Insert an allen wrench into the hole in the inside screw

and the hole in the rod to prevent the rod from spin-

ning.

3. Remove the two (2) hex screws securing the inside screw

to the seat crossmember.

4. Repeat STEPS 2-3 for the outside screw.

5. Remove the existing turnbuckle assembly from the seat

and frame crossmembers.

6. Rotate the NEW turnbuckle until an equal number

of threads shows on either end.

7. Position the NEW turnbuckle assembly with the jam nut

towards the seat crossmember as shown in FIGURE 5.

8. Position the inside screw between the tabs on the seat

crossmember.

9. Insert an allen wrench into the hole in the inside screw

and the hole in the rod to prevent the rod from spin-

ning.

10. Apply a removable thread locker to the threads of

one (1) hex screw.

11. Install the hex screw into one end of the inside screw to

secure the turnbuckle assembly to the seat crossmember.

12. Repeat STEPS 10-11 for opposite end of inside screw.

13. Repeat STEPS 8-12 to secure the outside screw to the

frame crossmember.

FIGURE 5 - REPLACING TURNBUCKLE ASSEMBLY -

A-6/A-6S ONLY

Inside Screw

Hole

Rod

Seat

Crossmember

Flange

Hex

Screws

Outside Screw

Frame Crossmember

Hex

Screws

Turnbuckle

Jam Nut

Threads

PROCEDURE 4 FRAME

F

R

A

M

E

Ta b

Hole

OPENING/CLOSING CLAMPS

(FIGURE 6)

WARNING

QUICK RELEASE LEVERS - Make sure the quick re-

lease levers are in the CLOSED position BEFORE

using the wheelchair, otherwise personal injury or

damage to the wheelchair may result.

STANDARD CAMBER OR RECEIVER TUBE CLAMPS

- Make sure the hex screws and locknuts are se-

curely tightened BEFORE using the wheelchair,

otherwise personal injury or damage to the

wheelchair may result.

CAUTION

DO NOT close the quick-release levers or tighten the

hex screws and locknuts without camber inserts in

the axle tube. Damage to the axle tube will occur.

Camber Clamps

1. Perform one (1) of the following to open a camber clamp:

A. QUICK RELEASE LEVERS - Pull the quick re-

lease lever to the open position.

B. STANDARD CAMBER CLAMPS - Loosen, but

do not remove the hex screw and locknut on the

camber clamp.

2. Perform one (1) of the following to close a camber clamp:

A. QUICK RELEASE LEVERS - Tighten the

threaded knob to secure the quick release lever.

Push the quick release lever on the camber

clamps to the closed position.

B. STANDARD CAMBER CLAMPS - Securely tighten

the hex screw and locknut to secure the axle tube.

Receiver Tube Clamps

1. Perform one (1) of the following to open a receiver

tube clamp:

A. QUICK RELEASE LEVERS - Pull the quick re-

lease levers on the receiver tube clamps to the

open position.

B. STANDARD RECEIVER TUBE CLAMPS -

Loosen, but do not remove the hex screws and

locknuts on the receiver tube clamps.

2. Perfrom one (1) of the following to close a receiver

tube clamp:

A. QUICK RELEASE LEVERS - Tighten the

threaded knob to secure the quick release lever.

Push the quick release lever on the receiver tube

clamps to the closed position.

B. STANDARD RECEIVER TUBE CLAMPS -

Tighten the hex screw and locknut on the re-

ceiver tube clamp. Torque to 75 in./lbs.