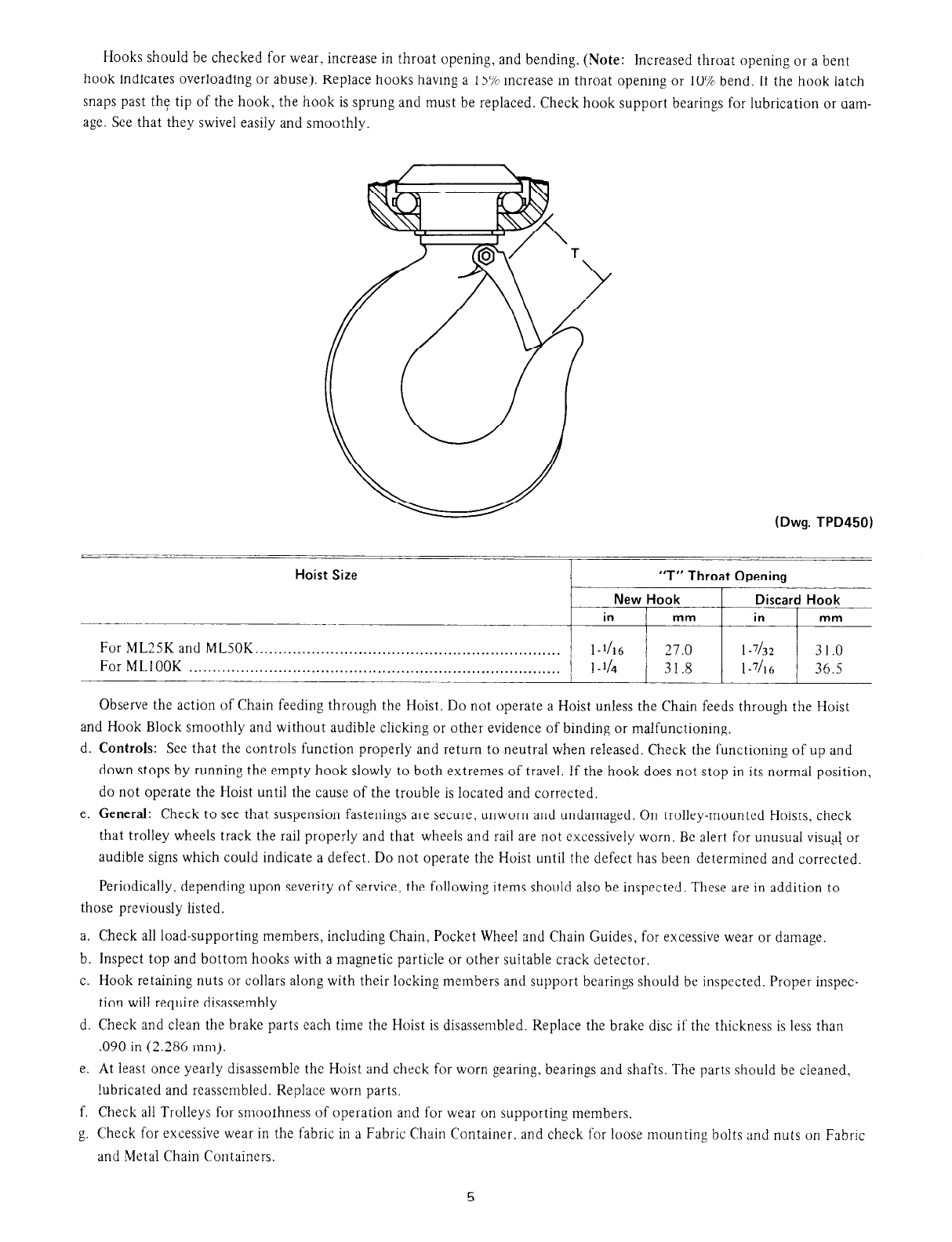

Hooks should be checked for wear. increase in throat opening, and bending.

(Note:

Increased throat opening or a bent

hook indicates overloading or abuse). Replace hooks having a 15% increase in throat opening or 10% bend. If the hook latch

snaps past the tip of the hook, the hook is sprung and must be replaced. Check hook support bearings for lubrication or dam-

age. See that they swivel easily and smoothly.

(Dwg. TPD450)

Hoist Size

For ML25K and

MLS0K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

For ML100K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

“T” Throat Opening

New Hook Discard Hook

in mm

in

mm

1-1/6

27.0

l-7/32

31.0

I-1/4

31.8

l-7/16 36.5

Observe the action of Chain feeding through the Hoist. Do not operate a Hoist unless the Chain feeds through the Hoist

and Hook Block smoothly and without audible clicking or other evidence of binding or malfunctioning.

d. Controls: See that the controls function properly and return to neutral when released, Check the functioning of up and

down stops by running the empty hook slowly to both extremes of travel. If the hook does not stop in its normal position,

do not operate the Hoist until the cause of the trouble is located and corrected.

e. General: Check to see that suspension fastenings are secure, unworn and undamaged. On trolley-mounted Hoists, check

that trolley wheels track the rail properly and that wheels and rail are not excessively worn. Be alert for unusual visual or

audible signs which could indicate a defect. Do not operate the Hoist until the defect has been determined and corrected.

Periodically, depending upon severity of service, the following items should also be inspected. These are in addition to

those previously listed.

a. Check all load-supporting members, including Chain, Pocket Wheel and Chain Guides, for excessive wear or damage.

b. Inspect top and bottom hooks with a magnetic particle or other suitable crack detector.

c. Hook retaining nuts or collars along with their locking members and support bearings should be inspected. Proper inspec-

tion will require disassembly.

d. Check and clean the brake parts each time the Hoist is disassembled. Replace the brake disc if the thickness is less than

.090 in (2.286 mm).

e. At least once yearly disassemble the Hoist and check for worn gearing, bearings and shafts. The parts should be cleaned,

lubricated and reassembled. Replace worn parts.

f. Check all Trolleys for smoothness of operation and for wear on supporting members.

g. Check for excessive wear in the fabric in a Fabric Chain Container. and check for loose mounting bolts and nuts on Fabric

and Metal Chain Containers.

5