19

LUBRICATION

To ensure continued satisfactory operation of the hoist, all

points requiring lubrication must be serviced with the

correct lubricant at the proper time intervals indicated for

each assembly. Correct lubrication is one of the most

important factors in maintaining efficient operation.

The lubrication intervals recommended in Table 6 are based

on intermittent operation of the hoist eight hours each day,

five days per week. If the hoist is operated almost

continuously, or for more than eight hours each day, or

under severe conditions, more frequent lubrication will be

required.

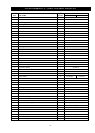

Table 6

LUBRICATION Frequency by usage level

Component

Severe

Heavy

Normal

Load chain

Daily

Weekly

At usage

Hook

Daily

Weekly

At usage

Gear case

Yearly

Every 3 years

Unnecessary

Lubricant types and change intervals are based on operation

in an environment relatively free of dust, moisture and

corrosive fumes. Use only those lubricants recommended.

Other lubricants may affect performance of the hoist.

Approval for the use of other lubricants must be obtained

from your Ingersoll-Rand Technical Support Department

or distributor. Failure to observe this precaution may result

in damage to the hoist and/or its associated components.

Whenever a hoist is disassembled for overhaul or

replacement of parts, lubricate as follows:

Brake and Gear Assemblies

The gear and brake assemblies share a common oil bath. On

larger capacity hoists, the output shaft from the motor is

offset and utilizes a pinion gear to drive the sun gear. These

gears operate in the motor casing oil bath.

Model

Gear Casing

(ml)

Motor Casing

(ml)

LC2A015S and

LC2A030D

150

N/A

LCA030S

LCA060D and

LCA070D

400

150

LCA060S

to

LCA250Q

750

150

LCA030S and Larger Hoists Oil Fill Level Positions

Fill to the level of the plug on the side of the motor

housing and on the gear end in the center of the brake

end cover.

Replace the oil in the brake and gear housing in accordance

with Table 6 recommendations. Refer to Table 8 for

recommended oil type. If hoist use is at normal frequency,

the oil in the reduction housing is suitable for one year's

operation without changing.

However, when hoist use is at greater frequency, or under

severe conditions, the oil may need to be changed more

often. To ensure correct performance, highest efficiency

and long life, it is essential that the lubricating oil be

maintained at the correct level. The recommended grade of

oil must be used at all times since the use of unsuitable oil

may result in excessive temperature rise, loss of efficiency

and possible damage to the gears.

Liftchain hoists are shipped from the factory with oil in the

brake and reduction gear assembly.

Table 8

Ambient Temperature

Recommendes Oil Type

Below (0°C)

ISO VG22 (50W)

(0° to 26°C)

ISO VG 150 (90W)

Above (26°C)

ISO VG 460 (140W)

Hook Assemblies

Hoist top and bottom hooks are supported by thrust

bearings. These bearings must be packed with Ingersoll-

Rand No. 68 Grease or a standard No. 2 multi-purpose

grease at regular intervals. Neglect of proper lubrication can

lead to bearing failure.

1. Lubricate the hook and latch pivot points. Hook and latch

should swivel/pivot freely.

2. Use Ingersoll-Rand LUBRI-LINK-GREEN ® or ISO

VG 220 (50W) lubricant.

3. Lubricate hook bearings by applying several shots of

grease from a grease gun to the grease fittings provided

on the hook blocks.

Air Line Lubricator

If an air line lubricator is used, it should be replenished

daily with ISO VG 100 (30W) lubricant (minimum

viscosity 135 Cst at 104° F (40° C)).

Trolley

Grease the wheel bearings and wheel drive gear with

Ingersoll-Rand No. 68 Grease or a standard No. 2 multi-

purpose grease periodically. Refer to the manufacturer's

literature for additional lubrication information.

Load Chain

WARNING

• Failure to maintain a clean and well-lubricated load

chain will result in rapid load chain wear that can lead

to chain failure which can cause severe injury, death or

substantial property damage.

1. Lubricate each link of the load chain weekly. Apply new

lubricant over existing layer.

2. In severe applications or corrosive environments,

lubricate more frequently than normal.

3. Lubricate hook and hook latch pivot points with same

lubricant used on the load chain.

4. If required, clean chain with acid free solvent to remove

rust or abrasive dust buildup and lubricate the chain.

5. Use Ingersoll-Rand LUBRI-LINK-GREEN ® or ISO

VG 220 (50W) oil.