AN200-EU-EN-V2.5-6/13

11

InfraRed Measurement Considerations

When taking IR measurements the meter automatically compensates for ambient temperature

changes. Note that it may take up to 30 minutes to adjust to extremely wide ambient changes.

Low temperature measurements quickly followed by high temperature measurements may

require several minutes to stabilize as a result of the IR sensor cooling process.

If the surface of the object under test is covered with frost, oil, grime, etc., clean before taking

measurements.

If an object's surface is highly reflective apply masking tape or flat black paint before measuring.

Steam, dust, smoke, etc. can obstruct measurements.

To find a hot spot, aim the meter outside the area of interest then scan across (in an up and

down motion) until the hot spot is located.

IR Theory

IR thermometers measure the surface temperature of an object. The meter’s optics sense emitted,

reflected, & transmitted energy that is collected and focused onto the meter’s detector. The meter’s

circuitry translates this information into an LCD reading.

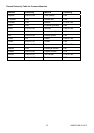

IR Field of View

Ensure that the desired target is larger than the spot size as shown in the diagram below. As the

distance from an object increases, the spot size of the area measured by the meter becomes larger.

The meter’s field of view ratio is 8:1, meaning that if the meter is 8 inches from the target, the

diameter (spot) of the object under test must be at least 1 inch. Other distances are shown below in

the field of view diagram.

Emissivity

Most organic materials and painted or oxidized surfaces have an emissivity of 0.95. Inaccurate

readings will result when measuring shiny or polished surfaces. To compensate, cover the surface

under test with masking tape or flat black paint. Allow time for the tape to reach the same

temperature as the material underneath then measure the temperature of the tape or the painted

surface.