SYSTEMS DESCRIPTIONS

HAZARD

CAUTION!

ESD

K1

K2

U1

D12

51

U9

76

26

1

R10

R11

U13

U14

U15

1413

2

1

4 7

6

5

11 12

J7

3

109

8

J4

J5

100218-

REVISION

U2

U8

U11

U12

J10

1 9

2 1010

9

2

1

F1

J1

U7

U5

Y1

U6

U3

61

41

21

1

U4

J9

5 3

J8

4 12

AZ987-2C

AZ987-2C

D13

C20

D15

D16

D14

C19

D7

D2

AZ987-2C

F3

J6

12

6

7

1

J3

D17

D18

+

+

C24

Q5

S1

S2

1

J14

2 3

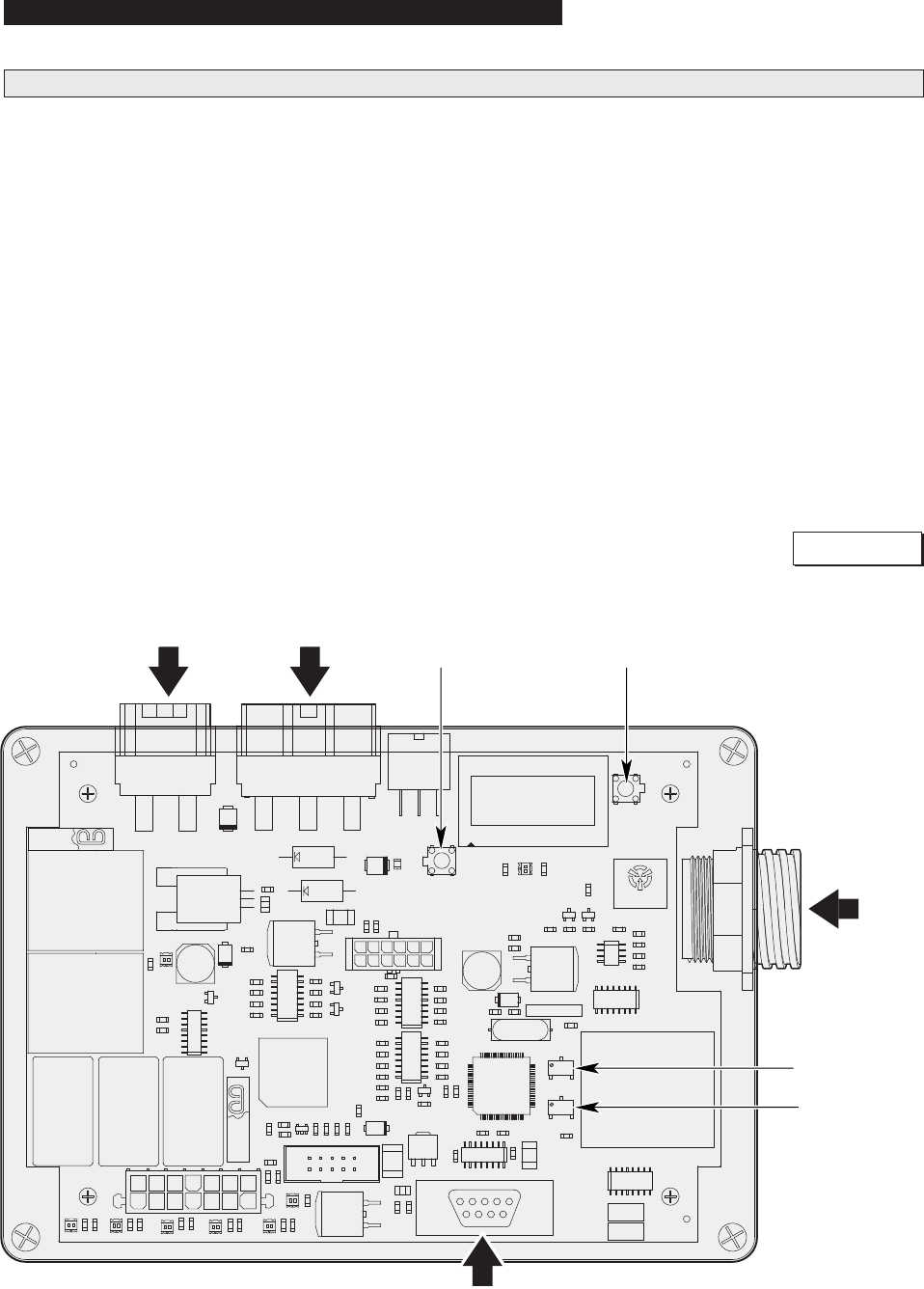

Manual Calibration Instructions for Controller

Figure S

Power

Harness

Port

Ramp

Harness

Port

Data

Harness

Port

J9 Port

Calibrate

Button

Stow Limit

Potentiometer

Deploy Limit

Potentiometer

Calibrate

Reset Button

Press the “Calibrate” button. Once pressed, the

calibrate LED should turn on.

Adjust the Deploy Limit potentiometer to the obstruc-

tion sensing level desired (see Figure S). Rotating

the potentiometer counterclockwise increases the

force that the ramp will exert when it is deploying.

Caution: Ensure that the force exerted is not exces-

sive. It is recommended to adjust the potentiometer

in small amounts and check operation after each

adjustment.

Adjust the Stow Limit potentiometer to the obstruc-

tion sensing level desired. Rotating the potentiom-

eter counterclockwise increases the force that the

ramp will exert when it is stowing.

Caution: Ensure that the force exerted is not exces-

sive. It is recommended to adjust the potentiometer

in small amounts and check operation after each

adjustment.

Once the desired force levels are reached, press the

“Calibrate” button a second time to store the set-

tings. Ensure the calibrate LED is off before return-

ing the ramp to service.

Page 35